The Advantages of Using Hydraulic Three-Ram BOP Spots for Enhanced Safety

2025-05-13

The Advantages of Using Hydraulic Three-Ram BOP Spots for Enhanced Safety

Table of Contents

- Introduction: Understanding the Importance of Safety in Drilling Operations

- What is a Hydraulic Three-Ram BOP?

- How Hydraulic Three-Ram BOP Works: A Breakdown

- Advantages of Hydraulic Three-Ram BOP for Enhanced Safety

- Improved Pressure Control

- Increased Reliability in Emergency Situations

- Efficiency and Speed of Operation

- Versatility in Various Applications

- Applications of Hydraulic Three-Ram BOP in the Oil and Gas Industry

- Maintenance and Safety Protocols for Hydraulic Three-Ram BOP

- Frequently Asked Questions (FAQs)

- Conclusion: The Future of Safety in Drilling Operations

Introduction: Understanding the Importance of Safety in Drilling Operations

In the realm of oil and gas extraction, safety is paramount. The potential hazards associated with drilling operations necessitate robust safety measures to protect personnel, the environment, and equipment. One of the critical components in ensuring this safety is the Blowout Preventer (BOP), specifically the hydraulic three-ram BOP. This article delves into the advantages of hydraulic three-ram BOP spots, highlighting their role in enhancing safety across drilling operations.

What is a Hydraulic Three-Ram BOP?

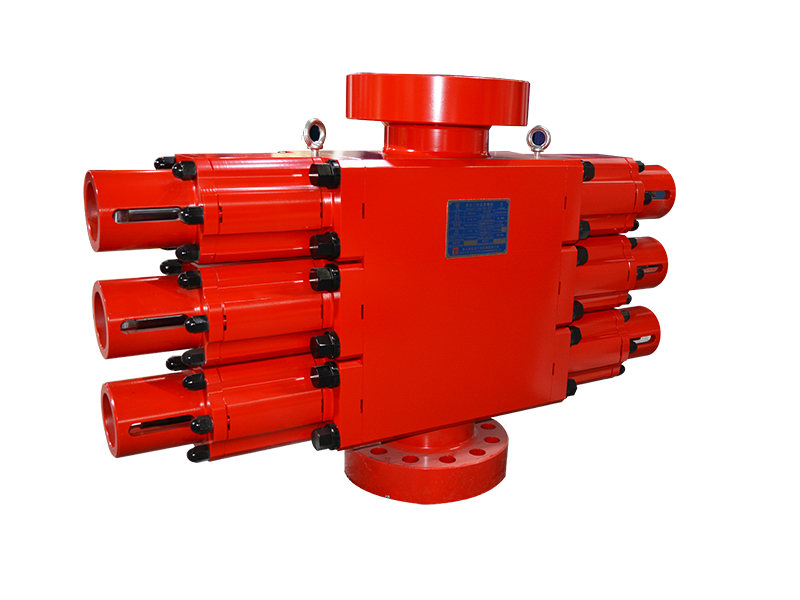

A hydraulic three-ram BOP is an advanced safety device used in drilling operations. It is designed to seal the wellbore in the event of an unexpected pressure surge, thereby preventing blowouts—an uncontrolled release of crude oil or natural gas from a well. The three-ram configuration consists of three rams that can close off the wellbore in various scenarios, providing a comprehensive safety solution for any drilling operation.

How Hydraulic Three-Ram BOP Works: A Breakdown

The operation of a hydraulic three-ram BOP is based on hydraulic pressure, which actuates the rams to close off the wellbore. When a pressure anomaly is detected, the system is activated, and the rams deploy to seal the well instantly. The hydraulic system ensures that the rams function accurately and efficiently, even under extreme pressures. The design of the BOP allows for flexible operation, accommodating different bore sizes and pressure levels, making it a vital tool for safety in the oil and gas industry.

Advantages of Hydraulic Three-Ram BOP for Enhanced Safety

Improved Pressure Control

Hydraulic three-ram BOPs are engineered to provide superior pressure control. With their ability to handle high-pressure situations, they significantly reduce the risk of blowouts. The precise hydraulic mechanisms allow for quick adjustments and responses to pressure changes, ensuring that drilling operations remain stable and under control.

Increased Reliability in Emergency Situations

In emergency situations, the reliability of safety equipment can mean the difference between a minor incident and a catastrophic failure. Hydraulic three-ram BOPs are built with robust materials and technology, ensuring they perform reliably when needed most. This reliability instills confidence in drilling teams, knowing they have a dependable safety net.

Efficiency and Speed of Operation

Time is of the essence in drilling operations. Hydraulic three-ram BOPs are designed for rapid deployment, allowing for swift action in critical moments. The hydraulic system enables quick activation of the rams, which can be pivotal in preventing blowouts. This efficiency not only enhances safety but also aids in minimizing operational downtime, leading to increased productivity.

Versatility in Various Applications

The hydraulic three-ram BOP’s design allows it to be used in various drilling conditions and environments, including offshore and onshore operations. Its versatility makes it suitable for different drilling rigs and well designs. This adaptability ensures that safety standards can be maintained across diverse operational scenarios.

Applications of Hydraulic Three-Ram BOP in the Oil and Gas Industry

Hydraulic three-ram BOPs play a crucial role in multiple applications within the oil and gas industry. They are primarily utilized in:

1. **Exploratory Drilling:** Ensuring safety during the initial stages of drilling and minimizing risks associated with discovering oil and gas reserves.

2. **Production Operations:** Protecting against pressure surges that may occur while extracting resources from the well.

3. **Workover Operations:** Providing safety during maintenance and repair activities on existing wells, where pressure control is vital.

The use of hydraulic three-ram BOPs across these applications underscores their importance in maintaining safety and operational integrity.

Maintenance and Safety Protocols for Hydraulic Three-Ram BOP

The effectiveness of hydraulic three-ram BOPs relies not only on their design but also on proper maintenance and adherence to safety protocols. Regular inspections and maintenance checks are essential to ensure optimal performance. This includes:

- **Routine Testing:** Periodic testing of the hydraulic system to confirm that the rams deploy correctly under pressure.

- **Preventive Maintenance:** Addressing potential issues before they escalate, such as replacing worn components and ensuring hydraulic fluid levels are adequate.

- **Training for Personnel:** Ensuring all operational staff are trained in using the hydraulic three-ram BOP effectively, understanding its mechanisms, and knowing emergency procedures.

By implementing these practices, drilling operations can maximize the effectiveness of hydraulic three-ram BOPs and enhance overall safety.

Frequently Asked Questions (FAQs)

1. What is the primary function of a hydraulic three-ram BOP?

The primary function of a hydraulic three-ram BOP is to seal the wellbore during drilling operations to prevent blowouts, thereby ensuring the safety of personnel and the environment.

2. How does the hydraulic system in a three-ram BOP work?

The hydraulic system operates by using hydraulic fluid to actuate the rams. When pressure changes are detected, the system deploys the rams to close off the well instantly.

3. Why are hydraulic three-ram BOPs preferred over other types?

Hydraulic three-ram BOPs are preferred due to their superior pressure control, reliability in emergencies, and quick response times, making them essential for safe drilling operations.

4. What maintenance is required for hydraulic three-ram BOPs?

Routine maintenance includes periodic testing, preventive maintenance, and training personnel on proper usage and emergency procedures to ensure optimal performance.

5. Can hydraulic three-ram BOPs be used in offshore drilling?

Yes, hydraulic three-ram BOPs are designed for versatility and can be effectively utilized in offshore drilling operations as well as onshore applications.

Conclusion: The Future of Safety in Drilling Operations

The hydraulic three-ram BOP represents a significant advancement in safety technology within the oil and gas industry. Its design, efficiency, and reliability make it a crucial component in preventing blowouts and ensuring safe drilling operations. As we move forward, continued innovation and adherence to safety protocols will enhance the effectiveness of hydraulic three-ram BOPs, ensuring that safety remains at the forefront of drilling practices. By investing in these advanced safety systems, the industry can foster a safer working environment and protect valuable resources for future generations.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China