Understanding the Advantages of Fully Sealed Shear Rams in Industrial Applications

2025-06-02

Understanding the Advantages of Fully Sealed Shear Rams in Industrial Applications

Table of Contents

- 1. Introduction to Fully Sealed Shear Rams

- 2. What Are Fully Sealed Shear Rams?

- 3. Benefits of Fully Sealed Shear Rams

- 3.1 Enhanced Safety Features

- 3.2 Improved Reliability and Durability

- 3.3 Operational Efficiency in Various Conditions

- 3.4 Low Maintenance Requirements

- 4. Applications of Fully Sealed Shear Rams

- 5. Technical Specifications of Fully Sealed Shear Rams

- 6. Comparison with Traditional Shear Rams

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to Fully Sealed Shear Rams

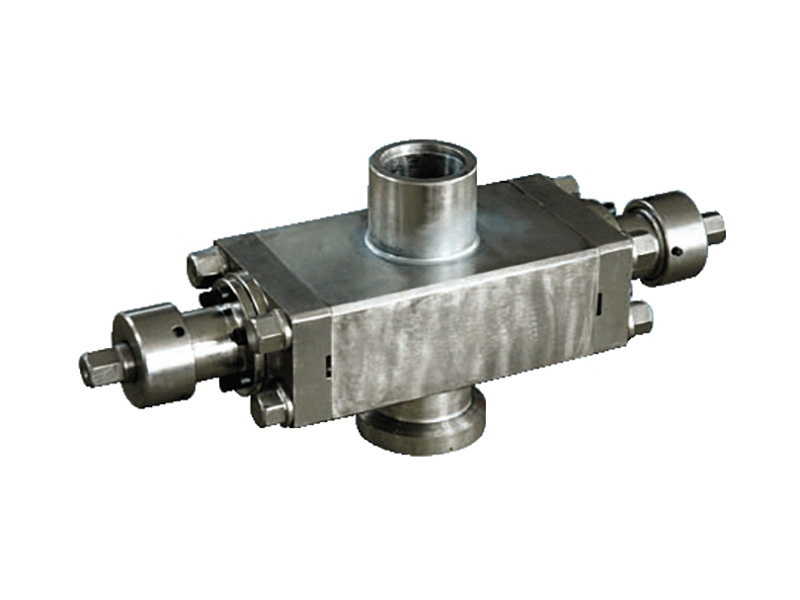

Fully sealed shear rams are specialized hydraulic devices designed to provide reliable and effective cutting capabilities in high-pressure environments. Their unique design and sealing mechanisms allow them to operate in harsh conditions, making them pivotal in industries such as oil and gas, marine, and construction. This article delves into the numerous benefits offered by fully sealed shear rams, shedding light on their applications and technical specifications.

2. What Are Fully Sealed Shear Rams?

Fully sealed shear rams are hydraulic tools designed for cutting through materials with ease. Unlike traditional shear rams, which may be susceptible to environmental factors like debris and pressure fluctuations, fully sealed shear rams feature robust seal designs that prevent contamination and ensure optimal performance. This makes them ideal for critical applications where precision and safety are paramount.

3. Benefits of Fully Sealed Shear Rams

3.1 Enhanced Safety Features

One of the standout features of fully sealed shear rams is their enhanced safety capabilities. The sealing design minimizes the risk of hydraulic fluid leaks, which can pose significant safety hazards in high-pressure environments. Moreover, their ability to operate without the fear of contamination increases the overall safety of operations, reducing the likelihood of accidents caused by equipment failure.

3.2 Improved Reliability and Durability

Fully sealed shear rams are built to withstand the rigors of demanding industrial applications. Their sealed mechanisms effectively shield internal components from external contaminants, enhancing their reliability and longevity. This durability translates to fewer equipment failures and reduced downtime, ensuring that operations run smoothly and efficiently.

3.3 Operational Efficiency in Various Conditions

These shear rams excel in diverse operating conditions, from extreme temperatures to high-pressure environments. Their robust design allows them to maintain operational efficiency regardless of external factors, enabling teams to complete tasks more quickly and with greater precision. This adaptability is crucial in industries where time and accuracy are critical.

3.4 Low Maintenance Requirements

Maintenance can often be a significant concern for industrial equipment. However, fully sealed shear rams require minimal upkeep due to their design. The seals prevent dirt and debris from entering critical areas, reducing wear and tear on components. This not only saves time and money on maintenance but also extends the operational lifespan of the equipment.

4. Applications of Fully Sealed Shear Rams

Fully sealed shear rams are versatile tools used across various sectors. Below are some of the key applications where these devices shine.

4.1 Oil and Gas Industry

In the oil and gas sector, fully sealed shear rams play a crucial role in blowout prevention and well control. Their ability to operate under high-pressure conditions allows for effective sealing and cutting, essential for maintaining safety during drilling operations.

4.2 Marine Applications

The marine industry also benefits from fully sealed shear rams, particularly in subsea operations. Their resistance to corrosion and ability to function in saltwater environments make them indispensable tools for underwater cutting and sealing tasks.

4.3 Construction and Demolition

In construction and demolition, fully sealed shear rams are utilized for cutting through steel, concrete, and other tough materials. Their precision and efficiency lead to faster project completion times and improved safety for workers on-site.

5. Technical Specifications of Fully Sealed Shear Rams

Understanding the technical specifications of fully sealed shear rams can help businesses choose the right equipment for their needs. Key specifications include:

- **Operating Pressure:** Most fully sealed shear rams can operate at pressures ranging from 5,000 to 15,000 psi.

- **Cutting Capacity:** Depending on the model, these rams can cut through materials up to several inches thick.

- **Material Composition:** Typically constructed from high-strength alloys, these shear rams are designed to resist wear and corrosion.

6. Comparison with Traditional Shear Rams

When comparing fully sealed shear rams to traditional models, several distinctions emerge. Traditional shear rams may lack effective sealing mechanisms, making them vulnerable to contamination and operational issues. In contrast, fully sealed shear rams provide superior protection, resulting in higher reliability, safety, and efficiency.

Additionally, traditional shear rams often require more frequent maintenance and may have shorter lifespans, increasing overall operational costs.

7. Frequently Asked Questions (FAQs)

What is the primary advantage of fully sealed shear rams?

The primary advantage lies in their enhanced safety and reliability, thanks to their superior sealing mechanisms that protect against contamination and hydraulic fluid leaks.

How do fully sealed shear rams perform in extreme conditions?

These rams are designed to operate efficiently in a wide range of conditions, including high pressure and extreme temperatures, making them extremely versatile.

What maintenance is required for fully sealed shear rams?

Due to their design, fully sealed shear rams require minimal maintenance. Regular inspections and cleaning are typically sufficient to ensure optimal performance.

Can fully sealed shear rams be used in underwater applications?

Yes, fully sealed shear rams are highly effective in underwater applications, especially in the marine industry, where they resist corrosion and function well in saltwater environments.

Are fully sealed shear rams more expensive than traditional shear rams?

While the initial investment may be higher, the long-term benefits of durability, reliability, and reduced maintenance costs often make fully sealed shear rams a more economical choice.

8. Conclusion

Fully sealed shear rams represent a significant advancement in cutting technology, offering unparalleled benefits in safety, reliability, and operational efficiency. Their unique design makes them indispensable tools across various industries, from oil and gas to construction. By investing in fully sealed shear rams, companies can enhance their operational capabilities while ensuring the safety of their workforce and equipment. As industries continue to evolve, the importance of reliable and efficient cutting solutions will only grow, solidifying the role of fully sealed shear rams in modern industrial applications.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China