The Evolution of Blowout Prevention: Focus on Double Ram Systems

2025-06-12

The Evolution of Blowout Prevention: Focus on Double Ram Systems

Table of Contents

1. Understanding Blowout Prevention Systems

2. Historical Context: The Need for Blowout Prevention

3. The Role of Double Ram Systems in Blowout Prevention

4. Advantages of Double Ram Systems Over Other Technologies

4.1 Enhanced Safety Features

4.2 Increased Reliability and Efficiency

5. Components of Double Ram Systems

5.1 Rams and Their Functionality

5.2 Hydraulic Systems and Control Mechanisms

6. Installation and Maintenance Best Practices

6.1 Key Considerations for Installation

6.2 Routine Maintenance Procedures

7. Future Trends in Blowout Prevention Technology

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Understanding Blowout Prevention Systems

Blowout prevention systems are critical components in the oil and gas extraction industry, designed to prevent the uncontrolled release of crude oil or natural gas from a well. When drilling, high-pressure formations can exceed the pressure exerted by drilling fluids, leading to catastrophic blowouts. Blowout preventers (BOPs) act as essential safeguards, ensuring the safety of personnel and equipment while maintaining control over well pressures.

2. Historical Context: The Need for Blowout Prevention

The oil and gas industry has faced numerous well blowouts throughout its history, resulting in significant environmental disasters, loss of life, and economic repercussions. The infamous blowout at the Ixtoc I well in 1979 and more recently, the Deepwater Horizon incident in 2010, emphasized the need for robust blowout prevention systems. These incidents led to advancements in technology, sparking the evolution of blowout preventers, including the double ram system, which has become a preferred choice in modern drilling operations.

3. The Role of Double Ram Systems in Blowout Prevention

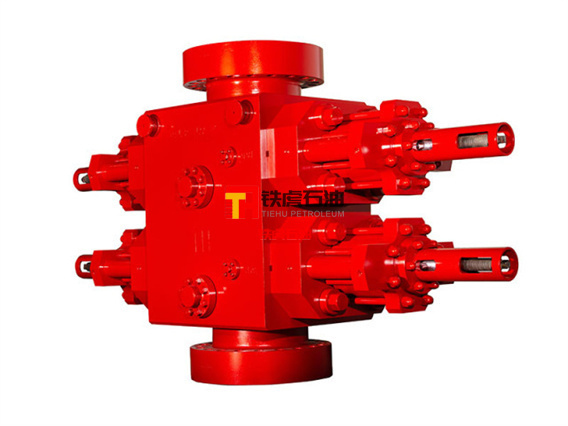

Double ram systems are designed with twin rams that work simultaneously to seal off the wellbore. This dual functionality enhances the control over well pressures and provides a higher level of safety compared to single ram systems. The evolution of double ram technology has allowed drilling operators to efficiently manage unexpected pressure surges, ensuring that operations can continue with minimal risk.

4. Advantages of Double Ram Systems Over Other Technologies

4.1 Enhanced Safety Features

The primary advantage of double ram systems is their superior safety features. By employing two rams, these systems provide a redundant mechanism for sealing the wellbore. In case one ram fails, the other remains operational, thereby significantly reducing the likelihood of blowouts. This redundancy is crucial in high-pressure environments typical of deep-water drilling.

4.2 Increased Reliability and Efficiency

Double ram systems offer increased reliability due to their robust design and operational capabilities. They are engineered to withstand extreme conditions, making them ideal for use in deep-water operations where pressure and temperature fluctuate dramatically. The efficiency of double ram systems also stems from their ability to quickly react to sudden pressure changes, minimizing downtime during drilling operations.

5. Components of Double Ram Systems

Understanding the components of double ram systems is essential for grasping how they function effectively in blowout prevention.

5.1 Rams and Their Functionality

The primary components of a double ram system are the rams themselves. Each ram is designed to seal against the wellbore, preventing fluid escape. They can be configured in various ways, such as blind rams, which seal the well completely, and pipe rams, which grip around drill pipes. The choice of ram type depends on the specific requirements of the drilling operation.

5.2 Hydraulic Systems and Control Mechanisms

Hydraulic systems power the movement of the rams in double ram systems. These hydraulic controls allow for precise operation, enabling the rams to engage and disengage as necessary. Advanced control mechanisms, including remote operation capabilities, enhance the safety and efficiency of these systems, allowing operators to manage blowout prevention from a safe distance.

6. Installation and Maintenance Best Practices

To ensure the continued effectiveness of double ram systems, proper installation and maintenance are vital.

6.1 Key Considerations for Installation

When installing double ram systems, operators must consider several key factors, including wellbore conditions, pressure ratings, and compatibility with existing drilling equipment. Proper installation techniques, such as ensuring correct alignment and securing connections, are crucial to prevent future malfunctions.

6.2 Routine Maintenance Procedures

Routine maintenance is essential for the longevity and reliability of double ram systems. Regular inspections of hydraulic fluid levels, seal integrity, and ram functionality should be conducted. Additionally, operators should implement a proactive maintenance schedule, addressing any wear and tear before it leads to system failure.

7. Future Trends in Blowout Prevention Technology

As the oil and gas industry continues to evolve, so do the technologies used for blowout prevention. Emerging trends include the integration of artificial intelligence and machine learning to predict pressure changes and enhance decision-making processes in real time. The development of more advanced materials for rams and seals is also on the horizon, promising even greater reliability and performance.

8. Frequently Asked Questions (FAQs)

What is a blowout preventer?

A blowout preventer (BOP) is a critical safety device used to control well pressure during drilling operations and prevent blowouts.

How do double ram systems work?

Double ram systems utilize two rams to seal the wellbore, providing redundancy and enhancing safety during drilling operations.

What are the advantages of using double ram systems?

Double ram systems offer enhanced safety features, increased reliability, and improved efficiency compared to single ram systems.

What maintenance is required for double ram systems?

Routine inspections of hydraulic fluid levels, seal integrity, and ram functionality are essential for maintaining double ram systems.

What are the future trends in blowout prevention technology?

Future trends include the integration of AI and machine learning for predictive analytics and the development of advanced materials for greater reliability.

9. Conclusion

The evolution of blowout prevention systems, particularly the development and implementation of double ram systems, has significantly improved safety and reliability in the oil and gas drilling industry. As technology continues to advance, these systems will evolve further, ensuring that operators can effectively manage well pressures and mitigate the risks associated with blowouts. By understanding the components, advantages, and future trends of double ram systems, professionals in the industry can better prepare for the challenges that lie ahead in this critical field.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China