Why Double Ram Blowout Preventers Are Essential for Safety in Operations

2025-06-14

Why Double Ram Blowout Preventers Are Essential for Safety in Operations

Understanding Blowout Preventers: A Crucial Safety Tool

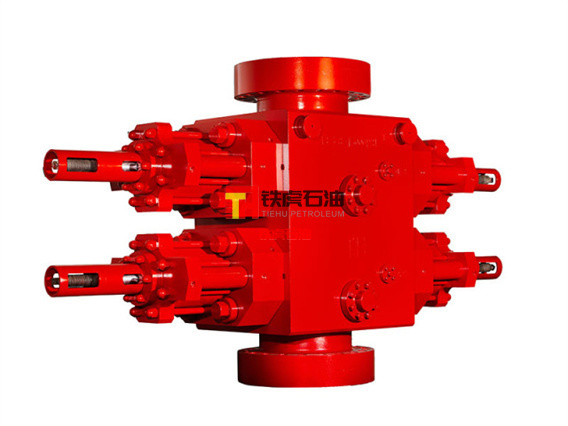

Blowout preventers (BOPs) are vital components in drilling operations, designed to prevent uncontrolled releases of crude oil or natural gas from a well. Among various types of BOPs, double ram blowout preventers stand out due to their robust safety features. They consist of two sets of rams that can close off the wellbore independently, providing added security against blowouts.

The Mechanics of Double Ram Blowout Preventers

Double ram BOPs employ two distinct types of rams—blind rams and shear rams. Each serves a unique purpose in emergency situations.

Blind Rams: Sealing the Well

Blind rams are designed to close off the wellbore completely. This is crucial in scenarios where drilling operations need to cease immediately. By sealing the well, blind rams prevent any potential flow of hydrocarbons, thereby mitigating the risk of a blowout.

Shear Rams: Cutting Through Obstructions

Shear rams serve a dual purpose. Not only do they seal the wellbore, but they can also cut through drill pipes or other obstructions that may impede safety. This feature is essential when an emergency situation arises and immediate action is necessary.

The Importance of Double Ram BOPs in Oil and Gas Operations

From offshore drilling platforms to onshore rigs, double ram BOPs play an indispensable role in ensuring safety during drilling operations. Their presence significantly reduces the likelihood of catastrophic blowouts.

Enhancing Operational Safety

In the oil and gas industry, safety is paramount. Double ram BOPs enhance operational safety by providing redundant systems that ensure well integrity. In the event of a failure in one ram, the other remains functional, offering an additional layer of protection.

Regulatory Compliance and Best Practices

Compliance with industry regulations is critical. The use of double ram BOPs aligns with safety best practices set by governing bodies such as the American Petroleum Institute (API) and the Bureau of Safety and Environmental Enforcement (BSEE). Employing these devices not only meets regulatory standards but also demonstrates a commitment to operational safety.

Operational Efficiency and Environmental Protection

The implications of blowouts extend beyond immediate safety concerns. They can lead to environmental disasters, financial losses, and reputational damage for companies involved.

Minimizing Environmental Risks

Blowouts can result in significant environmental degradation. By utilizing double ram BOPs, companies mitigate the risks of spills and leaks, protecting surrounding ecosystems. This proactive approach to safety showcases a commitment to environmental stewardship.

Cost Implications of Blowouts

The financial ramifications of a blowout can be staggering. From cleanup costs to regulatory fines, the impact on a company’s bottom line is significant. Investing in double ram BOPs is a strategic move to prevent blowouts, ultimately saving companies from costly repercussions.

Installation and Maintenance of Double Ram BOPs

Proper installation and maintenance of double ram BOPs are crucial for their effectiveness. Regular inspections and adherence to manufacturer guidelines ensure optimal performance.

Installation Best Practices

Installing double ram BOPs requires skilled personnel and precise adherence to operational protocols. A thorough understanding of the BOP's specifications is essential for successful implementation.

Routine Maintenance and Inspection

Routine maintenance checks are vital for ensuring that double ram BOPs function effectively during critical operations. Regular inspections should include checking hydraulic systems, seals, and mechanical components for wear and tear.

Training and Preparedness: Empowering Personnel

Even the best equipment cannot prevent blowouts without a well-trained team. Investing in personnel training is essential for effective blowout prevention.

Comprehensive Training Programs

Training programs should encompass equipment operation, emergency response procedures, and safety protocols. By empowering personnel with the knowledge and skills needed to operate double ram BOPs, companies enhance their safety culture.

Simulated Emergency Drills

Conducting simulated emergency drills ensures that team members can respond swiftly and effectively in crisis situations. Regular training simulations help to reinforce learned skills and prepare teams for real-life scenarios.

The Future of Blowout Prevention Technology

As the oil and gas industry continues to evolve, so does the technology surrounding blowout prevention. Innovations in materials, automation, and monitoring systems are paving the way for safer operations.

Smart BOP Systems

Emerging technologies are leading to the development of smart BOP systems that integrate real-time data monitoring and predictive analytics. These advancements enable operators to respond proactively to potential blowout scenarios.

Environmental Monitoring Technologies

With increasing environmental regulations, monitoring technologies are becoming essential. These systems provide real-time assessments of environmental impacts and help ensure compliance with regulatory standards.

Case Studies: Successful Implementation of Double Ram BOPs

Examining real-world examples underscores the effectiveness of double ram BOPs in preventing blowouts and enhancing operational safety.

Case Study 1: Offshore Drilling Success

In a recent offshore drilling project, the implementation of double ram BOPs led to the successful containment of a near blowout situation. The swift activation of the shear rams allowed for the safe resolution of the potential crisis.

Case Study 2: Onshore Rig Efficiency

An onshore drilling site experienced a significant reduction in operational downtime after integrating double ram BOPs into their safety protocols. The reliability of the systems ensured that potential blowouts were effectively managed.

Conclusion: A Commitment to Safety in Operations

The implementation of double ram blowout preventers is not merely a regulatory requirement but a commitment to safety in drilling operations. Their design, functionality, and the additional layers of protection they provide are indispensable in safeguarding personnel, the environment, and company assets. Investing in double ram BOPs enhances operational efficiency and demonstrates a proactive approach to risk management in the oil and gas industry.

FAQs about Double Ram Blowout Preventers

What is the primary function of double ram blowout preventers?

Double ram blowout preventers primarily function to prevent uncontrolled releases of fluids from a well, ensuring operational safety.

How do double ram BOPs differ from single ram BOPs?

Double ram BOPs feature two independent sets of rams for enhanced safety, while single ram BOPs utilize only one ram system.

What maintenance is required for double ram BOPs?

Routine inspections and maintenance checks of hydraulic systems, seals, and mechanical components are essential for ensuring their effectiveness.

How often should personnel training be conducted regarding BOP operations?

Regular training sessions should be conducted at least annually, with additional simulated emergency drills to reinforce skills.

What are the environmental benefits of using double ram BOPs?

Double ram BOPs help minimize the risk of blowouts, thereby protecting ecosystems from potential oil spills and environmental degradation.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China