Understanding the Importance of Double Ram Blowout Preventers in Safety and Protection

2025-06-15

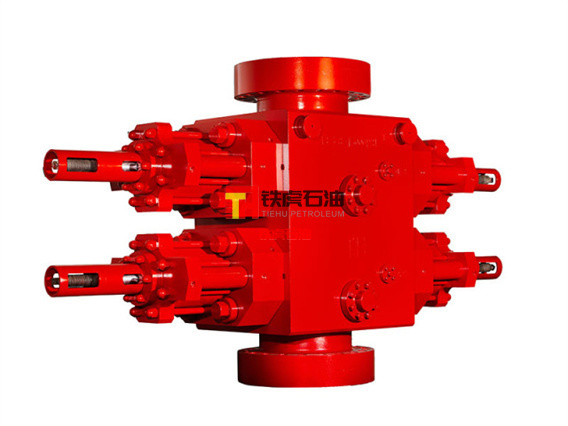

In the realm of safety and protection, particularly in industries involving drilling and extraction, the double ram blowout preventer (BOP) is an essential piece of equipment. This device is designed to control the flow of fluids during drilling operations and prevent uncontrolled releases, commonly referred to as blowouts. A blowout can not only result in significant financial loss but also pose serious risks to human safety and the environment. Consequently, understanding the functionality and importance of a double ram blowout preventer is vital for anyone involved in these operations.

A double ram blowout preventer features two sets of rams, which are essentially hydraulic mechanisms that can seal off the wellbore. When drilling occurs, there is always a risk of pressure buildup from gas or fluids, which can lead to a blowout if not managed effectively. The two rams in a double ram BOP work collaboratively to provide a robust barrier against these potential hazards. This dual-action capability enhances the reliability and safety of drilling operations, making it a preferred choice in high-risk environments.

One of the key advantages of a double ram blowout preventer is its ability to provide redundancy. In the event that one ram fails, the second ram can still execute its function, thereby ensuring continued protection. This redundancy is crucial in maintaining safety protocols and minimizing downtime in operations, which can be costly. Additionally, double ram BOPs can be designed to accommodate various well conditions, making them versatile and suitable for different operational requirements.

Moreover, the maintenance and regular testing of double ram blowout preventers are critical to their performance. Routine inspections, pressure tests, and functional checks are necessary to ensure that these devices operate reliably when needed most. Training personnel on the proper use and emergency procedures related to blowout preventers is also vital for enhancing safety protocols.

In conclusion, the double ram blowout preventer is a cornerstone of safety in drilling operations. Its dual ram design not only provides increased reliability but also ensures that personnel and the environment remain protected from the unpredictable forces of nature during drilling activities. Organizations involved in the safety and protection industry, particularly those focused on operational safety, should prioritize the implementation and maintenance of such crucial equipment. Understanding the functionality, advantages, and best practices associated with double ram blowout preventers will ultimately lead to safer and more efficient operations across the board.

A double ram blowout preventer features two sets of rams, which are essentially hydraulic mechanisms that can seal off the wellbore. When drilling occurs, there is always a risk of pressure buildup from gas or fluids, which can lead to a blowout if not managed effectively. The two rams in a double ram BOP work collaboratively to provide a robust barrier against these potential hazards. This dual-action capability enhances the reliability and safety of drilling operations, making it a preferred choice in high-risk environments.

One of the key advantages of a double ram blowout preventer is its ability to provide redundancy. In the event that one ram fails, the second ram can still execute its function, thereby ensuring continued protection. This redundancy is crucial in maintaining safety protocols and minimizing downtime in operations, which can be costly. Additionally, double ram BOPs can be designed to accommodate various well conditions, making them versatile and suitable for different operational requirements.

Moreover, the maintenance and regular testing of double ram blowout preventers are critical to their performance. Routine inspections, pressure tests, and functional checks are necessary to ensure that these devices operate reliably when needed most. Training personnel on the proper use and emergency procedures related to blowout preventers is also vital for enhancing safety protocols.

In conclusion, the double ram blowout preventer is a cornerstone of safety in drilling operations. Its dual ram design not only provides increased reliability but also ensures that personnel and the environment remain protected from the unpredictable forces of nature during drilling activities. Organizations involved in the safety and protection industry, particularly those focused on operational safety, should prioritize the implementation and maintenance of such crucial equipment. Understanding the functionality, advantages, and best practices associated with double ram blowout preventers will ultimately lead to safer and more efficient operations across the board.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China