Understanding the Role of Passive Rotary Blowout Preventers in Agricultural Machinery

2024-11-16

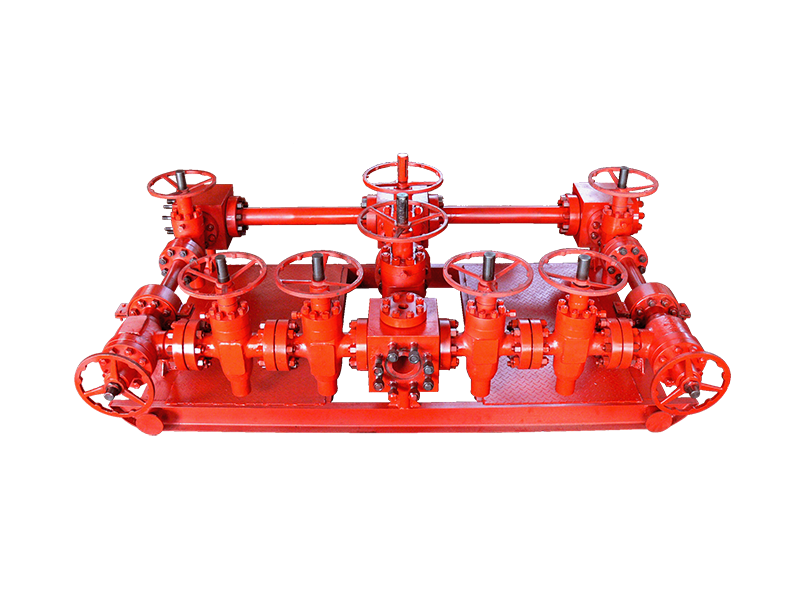

In the realm of agricultural machinery, safety and performance are paramount. One of the lesser-known yet vital components contributing to these aspects is the passive rotary blowout preventer (BOP). While commonly associated with oil drilling, the principles of BOPs can be extrapolated to various applications, including agricultural machinery used in field operations.

Passive rotary blowout preventers serve a crucial purpose in preventing uncontrolled releases of fluids and gases during operations. In agricultural contexts, these devices can help manage the pressures involved in various tasks, such as drilling for water or managing soil aeration processes. Their design inherently incorporates safety features that function without the need for external power sources, making them highly reliable in remote agricultural settings where such resources may be limited.

The operation of a passive rotary blowout preventer involves a series of valves and seals that close automatically in response to abnormal pressure levels. This self-activating feature is vital for protecting not only the machinery itself but also the surrounding environment and personnel. By containing potential blowouts, these devices help mitigate risks associated with agricultural operations, which can include soil erosion, contamination, and loss of vital resources.

Furthermore, the integration of passive rotary blowout preventers in modern agricultural machinery can lead to increased efficiency. By maintaining controlled pressure during operations, these systems can optimize performance, thereby reducing downtime and enhancing productivity. Farmers and agricultural businesses that adopt machinery equipped with advanced BOP technology may find themselves better equipped to handle the challenges posed by unpredictable environmental conditions.

While the primary function of passive rotary blowout preventers is centered around safety, their impact on operational efficiency cannot be overlooked. Understanding how these devices work and their benefits can empower agricultural professionals to make informed decisions regarding their machinery investments.

In summary, passive rotary blowout preventers are an essential component in the safe and efficient operation of agricultural machinery. By preventing uncontrolled pressure releases, they protect both the equipment and the environment, while also contributing to optimized performance. As the agricultural industry continues to evolve, the integration of technology like passive BOPs will likely play a critical role in shaping the future of field operations, ensuring that safety and efficiency remain at the forefront of agricultural practices.

Passive rotary blowout preventers serve a crucial purpose in preventing uncontrolled releases of fluids and gases during operations. In agricultural contexts, these devices can help manage the pressures involved in various tasks, such as drilling for water or managing soil aeration processes. Their design inherently incorporates safety features that function without the need for external power sources, making them highly reliable in remote agricultural settings where such resources may be limited.

The operation of a passive rotary blowout preventer involves a series of valves and seals that close automatically in response to abnormal pressure levels. This self-activating feature is vital for protecting not only the machinery itself but also the surrounding environment and personnel. By containing potential blowouts, these devices help mitigate risks associated with agricultural operations, which can include soil erosion, contamination, and loss of vital resources.

Furthermore, the integration of passive rotary blowout preventers in modern agricultural machinery can lead to increased efficiency. By maintaining controlled pressure during operations, these systems can optimize performance, thereby reducing downtime and enhancing productivity. Farmers and agricultural businesses that adopt machinery equipped with advanced BOP technology may find themselves better equipped to handle the challenges posed by unpredictable environmental conditions.

While the primary function of passive rotary blowout preventers is centered around safety, their impact on operational efficiency cannot be overlooked. Understanding how these devices work and their benefits can empower agricultural professionals to make informed decisions regarding their machinery investments.

In summary, passive rotary blowout preventers are an essential component in the safe and efficient operation of agricultural machinery. By preventing uncontrolled pressure releases, they protect both the equipment and the environment, while also contributing to optimized performance. As the agricultural industry continues to evolve, the integration of technology like passive BOPs will likely play a critical role in shaping the future of field operations, ensuring that safety and efficiency remain at the forefront of agricultural practices.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China