Innovative Solutions for Farming: The Role of Passive Rotary Blowout Preventers

2024-11-19

Innovative Solutions for Farming: The Role of Passive Rotary Blowout Preventers

Table of Contents

- Introduction to Passive Rotary Blowout Preventers in Agriculture

- Understanding Blowout Prevention: A Brief Overview

- Importance of Blowout Preventers in Modern Agriculture

- How Passive Rotary Blowout Preventers Work

- Key Benefits of Using Passive Rotary Blowout Preventers in Farming

- Case Studies: Successful Implementation of Blowout Preventers

- Challenges and Solutions in Implementing Blowout Preventers

- Future Trends in Agriculture: The Role of Technology

- Conclusion

- Frequently Asked Questions

Introduction to Passive Rotary Blowout Preventers in Agriculture

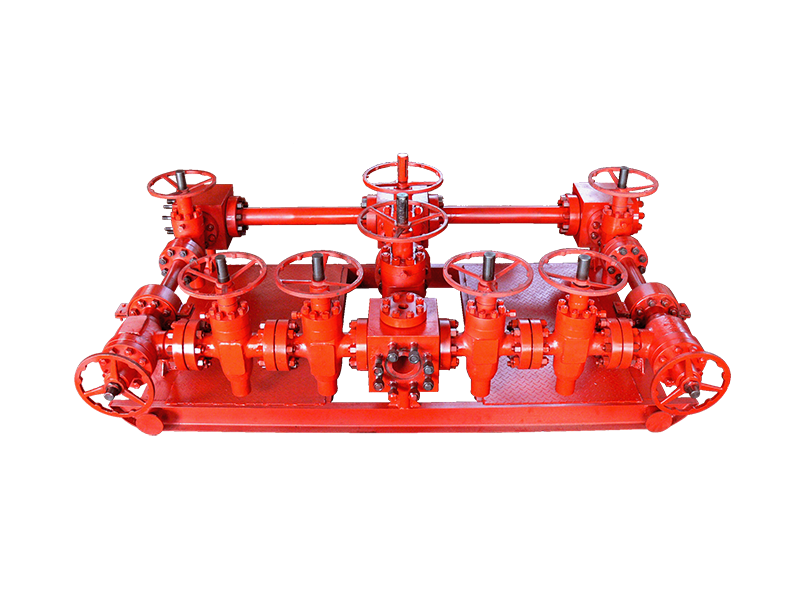

In today's fast-evolving agricultural landscape, innovative solutions are essential for enhancing efficiency and safety. One such innovation is the **passive rotary blowout preventer** (BOP), traditionally associated with the oil and gas sector, which is now making waves in farming practices. This article explores how these devices can transform agricultural operations, focusing on their functionality, benefits, and the implications for future farming methods.

Understanding Blowout Prevention: A Brief Overview

Blowout prevention is crucial in any industry that involves the handling of pressurized fluids. In agriculture, blowouts can occur during operations like soil drilling, where pressure build-up can lead to uncontrolled fluid release. A **passive rotary blowout preventer** is designed to automatically seal off the wellbore when pressure exceeds a predetermined limit, thereby preventing blowouts and ensuring safe operational conditions.

Importance of Blowout Preventers in Modern Agriculture

The significance of blowout preventers in agriculture cannot be overstated. As farmers increasingly turn to **advanced drilling techniques** for irrigation and soil management, the risk of blowouts rises. Implementing passive rotary blowout preventers not only enhances safety but also mitigates potential damage to crops and the environment.

Moreover, these devices contribute to operational efficiency by minimizing downtime and reducing the likelihood of accidents, which can be costly in terms of finances and reputation. By ensuring a controlled environment, farmers can focus on maximizing yield and sustainability, which are critical in today's market.

How Passive Rotary Blowout Preventers Work

Passive rotary blowout preventers operate based on the principle of pressure control. When the internal pressure within the wellbore exceeds a safe threshold, the device automatically engages to seal the well, preventing uncontrolled fluid release.

The key components of a passive rotary blowout preventer include:

- **Sealing Elements**: Made from durable materials, these are designed to withstand high pressure and temperature.

- **Control Mechanism**: Unlike active systems that require manual intervention, passive systems operate automatically, ensuring quick response to pressure changes.

- **Installation Features**: Easy to install and integrate with existing agricultural equipment, making them accessible for farmers of all scales.

Understanding the mechanics of these blowout preventers is crucial for farmers seeking to adopt them for enhanced safety and productivity.

Key Benefits of Using Passive Rotary Blowout Preventers in Farming

The adoption of **passive rotary blowout preventers** in agriculture presents numerous advantages:

1. Enhanced Safety

Safety is paramount in any farming operation. By automatically sealing off blowouts, these devices protect workers and equipment from potential hazards associated with fluid release.

2. Cost Efficiency

Reducing accidents and downtime translates to significant cost savings. Farmers can avoid the expenses related to accidents, equipment damage, and legal liabilities.

3. Environmental Protection

By preventing fluid spills, passive rotary blowout preventers help safeguard local ecosystems, minimizing the risk of contamination to soil and water sources.

4. Increased Operational Efficiency

Farmers can maintain focus on their core activities without the constant worry about blowouts, leading to better productivity and yield management.

Case Studies: Successful Implementation of Blowout Preventers

Several case studies illustrate the successful integration of passive rotary blowout preventers in agricultural practices:

Case Study 1: Large-Scale Irrigation

In a large agricultural operation focused on irrigation, the implementation of passive rotary blowout preventers significantly reduced the number of blowouts. The farm reported a 30% increase in operational uptime and reduced repair costs.

Case Study 2: Soil Management Techniques

A medium-sized farm specializing in soil management adopted blowout preventers during drilling processes. The result was fewer incidents of soil contamination and a notable improvement in crop yield due to improved soil conditions.

Challenges and Solutions in Implementing Blowout Preventers

Despite the benefits, several challenges may arise when integrating passive rotary blowout preventers into farming operations:

1. Initial Costs

While blowout preventers offer long-term savings, the initial investment can be a barrier for some farmers. To address this, financing options and subsidies can be explored.

2. Training and Knowledge Gaps

Farmers may lack the necessary knowledge to operate and maintain these systems effectively. Comprehensive training programs can bridge this gap, ensuring that staff are well-equipped to handle the technology.

3. Compatibility with Existing Equipment

Not all farming equipment is compatible with passive rotary blowout preventers. Conducting thorough research and consultations with manufacturers can help ensure proper integration.

Future Trends in Agriculture: The Role of Technology

The future of agriculture is poised for transformation, with technology playing a central role. As farmers increasingly adopt **precision agriculture** and **smart farming techniques**, passive rotary blowout preventers are likely to evolve further. Integrating IoT (Internet of Things) technology could allow for real-time monitoring and data analytics, enhancing decision-making processes.

Moreover, as sustainability becomes a more pressing concern, innovations in blowout prevention technology will likely focus on eco-friendly materials and designs, aligning with the industry's shift towards greener practices.

Conclusion

In conclusion, **passive rotary blowout preventers** represent a significant advancement in agricultural technology, providing essential safety and efficiency benefits. By preventing blowouts, they safeguard both workers and the environment while promoting operational excellence. As the industry continues to embrace innovative solutions, the role of these devices will expand, paving the way for a more sustainable and productive future in farming.

Frequently Asked Questions

1. What is a passive rotary blowout preventer?

A passive rotary blowout preventer is a safety device designed to automatically seal a wellbore when pressure exceeds safe limits, preventing blowouts during agricultural operations.

2. How do blowout preventers enhance safety in farming?

By mitigating the risks associated with uncontrolled fluid release, blowout preventers protect workers, equipment, and the environment, thereby enhancing overall safety.

3. Are there any maintenance requirements for passive rotary blowout preventers?

Yes, routine inspections and maintenance are essential to ensure the effective operation of blowout preventers, including checking seals and control mechanisms.

4. Can passive rotary blowout preventers be used with existing farming equipment?

Most passive rotary blowout preventers can be integrated with existing equipment, but it's essential to consult with manufacturers for compatibility.

5. What are the costs associated with implementing blowout preventers in farming?

Initial costs may vary based on the size of the operation and the specific type of blowout preventer. However, the long-term savings from reduced accidents and enhanced efficiency typically outweigh these costs.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China