Essential Safety Protocols for Using Affordable Three Ram Blowout Preventers in Agricultural Settings

2024-11-25

Essential Safety Protocols for Using Affordable Three Ram Blowout Preventers in Agricultural Settings

Table of Contents

- 1. Introduction to Three Ram Blowout Preventers

- 2. Importance of Safety Protocols in Agriculture

- 3. Understanding Three Ram Blowout Preventers

- 4. Key Safety Protocols for Using Three Ram Blowout Preventers

- 5. Maintenance Tips for Three Ram Blowout Preventers

- 6. Adhering to Safety Regulations and Standards

- 7. Importance of Training and Education

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Three Ram Blowout Preventers

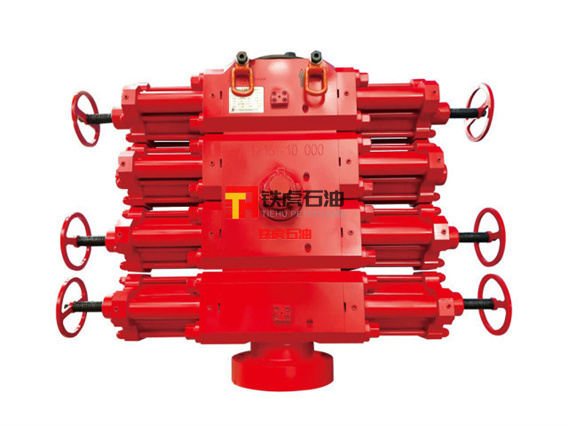

In the agricultural sector, effective management and prevention of blowouts during drilling operations are paramount. **Three ram blowout preventers (BOPs)** serve as critical safety devices designed to seal and control the flow of fluids, preventing uncontrolled releases of gases and liquids. Their affordability makes them a popular choice for various agricultural operations, but it is essential to use them safely and effectively.

2. Importance of Safety Protocols in Agriculture

Safety protocols are vital in any industry, but they take on added significance in agriculture due to the inherent risks involved. **Implementing robust safety measures** not only protects workers but also safeguards equipment and the environment. When using cheap three ram blowout preventers, the importance of these protocols cannot be overstated, as improper use can lead to catastrophic failures and accidents.

3. Understanding Three Ram Blowout Preventers

To ensure the safe operation of three ram blowout preventers, it is crucial to understand their design and functionality.

3.1 Types of Blowout Preventers

Various blowout preventers are available in the market, each with specific features and applications. The three ram configuration is particularly beneficial in agricultural settings due to its **high-pressure handling capabilities** and superior sealing performance. Understanding the types of BOPs available will help operators choose the right equipment for their needs.

3.2 How Three Ram Blowout Preventers Work

Three ram blowout preventers operate based on a series of hydraulic rams that can be engaged to seal the wellbore. When a well begins to flow uncontrollably, the rams can be activated to close off the well and control the pressure. This mechanism is essential for preventing blowouts, making it vital for operators to become familiar with how to engage and disengage these features effectively.

4. Key Safety Protocols for Using Three Ram Blowout Preventers

Implementing safety protocols is fundamental in ensuring safe operations with three ram blowout preventers. Below are some essential safety measures:

4.1 Pre-Use Safety Checks

Before engaging in any operational activities, it is essential to conduct comprehensive **pre-use safety checks**. These checks should include:

- Inspecting the BOP for any signs of wear or damage.

- Verifying that the hydraulic systems are functioning correctly.

- Ensuring all valves are operational and leak-free.

- Confirming that all safety equipment, such as pressure gauges, is in working order.

4.2 Operational Safety Measures

When operating three ram blowout preventers, it is crucial to follow established operational safety measures:

- Train all personnel on proper BOP operation.

- Maintain a clear communication line among team members.

- Monitor pressure levels continuously during operations.

- Establish a clear emergency response plan in case of a blowout.

4.3 Post-Use Procedures

After using three ram blowout preventers, it is important to follow **post-use procedures** to ensure equipment longevity and safety:

- Conduct a thorough inspection of the BOP for any damage or wear.

- Clean each component to prevent fluid contamination.

- Document all findings and maintenance activities for future reference.

5. Maintenance Tips for Three Ram Blowout Preventers

Regular maintenance is essential for the safe operation of three ram blowout preventers. Here are several maintenance tips:

- Schedule routine inspections according to manufacturer recommendations.

- Replace worn seals and components immediately to prevent leaks.

- Lubricate moving parts regularly to ensure smooth operation.

- Keep a detailed maintenance log to track any repairs or replacements.

6. Adhering to Safety Regulations and Standards

Compliance with safety regulations and standards is mandatory for all agricultural operations utilizing three ram blowout preventers. Operators should familiarize themselves with local, national, and industry-specific safety guidelines to ensure they are operating within legal frameworks. Regular audits and compliance checks can help maintain safety standards.

7. Importance of Training and Education

Investing in training and education for all personnel involved in operating three ram blowout preventers is vital. Regular training sessions should cover:

- Proper use and operation of BOPs.

- Emergency response protocols.

- Hazard recognition and risk assessment.

By fostering a culture of safety and continuous learning, operators can significantly reduce the risk of accidents and improve overall operational efficiency.

8. Conclusion

Using cheap three ram blowout preventers in agricultural settings presents unique challenges and responsibilities. By implementing robust safety protocols, performing regular maintenance, and investing in staff training, agricultural operators can mitigate risks associated with blowouts. Prioritizing safety not only protects personnel but also enhances the overall efficiency of agricultural operations, ensuring that projects are completed safely and effectively.

9. Frequently Asked Questions

What is a blowout preventer, and why is it important in agriculture?

A blowout preventer is a safety device used to prevent uncontrolled releases of oil, gas, or other fluids during drilling operations. It is crucial in agriculture to ensure the safety of operators and the environment.

How do I know if my three ram blowout preventer is functioning correctly?

Regular inspections and pre-use checks are essential. Look for any signs of wear, check that hydraulic systems are functioning, and ensure all seals and valves are leak-free.

What are the key safety protocols when using a blowout preventer?

Key protocols include pre-use safety checks, operational safety measures, and post-use procedures to maintain equipment integrity and ensure personnel safety.

How can I maintain my three ram blowout preventer?

Regular maintenance involves routine inspections, timely replacement of worn components, lubrication of moving parts, and keeping detailed maintenance logs.

Why is training important for personnel using blowout preventers?

Training ensures that all personnel are knowledgeable about proper operation, emergency procedures, and hazard recognition, significantly reducing the risk of accidents.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China