Understanding OEM Hydraulic Single Ram Blowout Preventers: Essential Tools for Safe Operations

2024-12-10

In the realm of manufacturing and construction machinery, particularly in the engineering and high-altitude work sectors, safety is paramount. One critical tool that underscores this commitment to safety is the OEM hydraulic single ram blowout preventer (BOP). Understanding its features, applications, and operational benefits can greatly enhance safety protocols and operational efficiency in various industries.

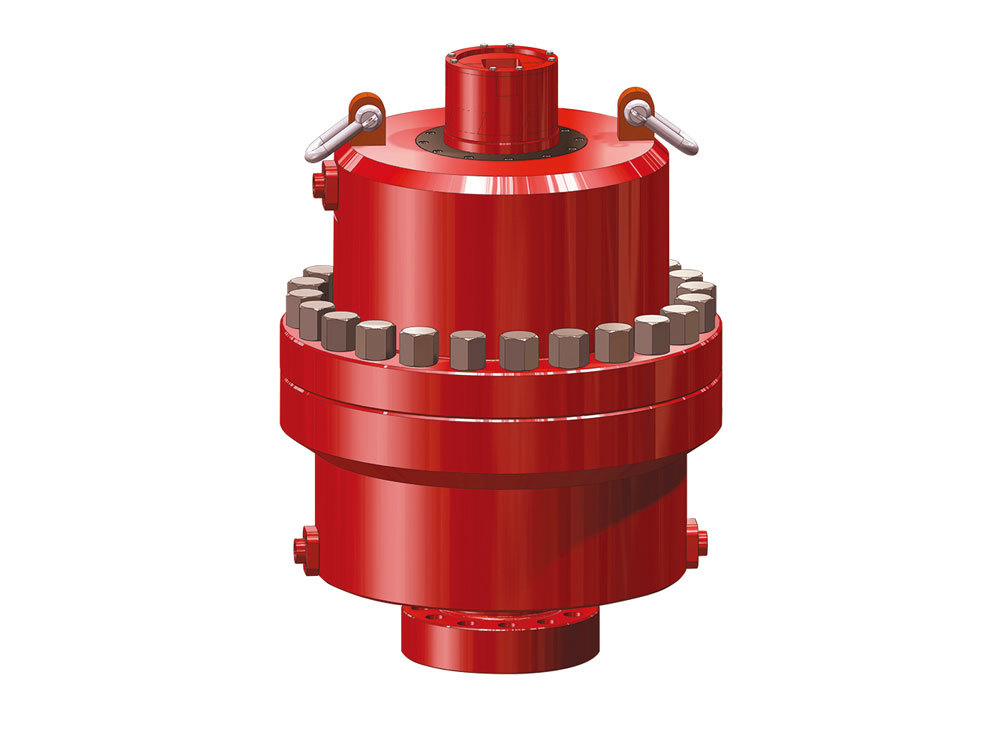

An OEM hydraulic single ram blowout preventer is a specialized device designed to control and prevent the uncontrolled release of fluids and gases during drilling operations. These devices are particularly crucial in oil and gas drilling but have applications in other high-pressure environments as well. The "single ram" refers to its design incorporating a single hydraulic mechanism that can seal the wellbore effectively, stopping any flow of fluid or gas when necessary.

The operation of a blowout preventer is predominantly hydraulic, utilizing pressurized fluids to actuate the device's rams. This hydraulic operation allows for swift engagement in emergency situations, providing a reliable barrier against potential blowouts. Such quick responses are crucial in preventing accidents that can lead to catastrophic events, environmental disasters, or significant operational delays.

Moreover, OEM hydraulic single ram blowout preventers are built to meet specific industry standards for operational efficiency and safety. The manufacturing of these devices often involves advanced engineering techniques and stringent quality controls, ensuring they can withstand high pressures and extreme conditions. This reliability is essential for companies that prioritize both the safety of their personnel and the integrity of their projects.

In addition to their primary function of preventing blowouts, these devices can also assist in pressure control during drilling operations, making them a versatile tool. They are particularly beneficial in environments where the pressures involved can vary significantly, providing a much-needed safety net.

Another significant advantage of using OEM products is that they are typically designed for compatibility with a range of existing equipment. This interoperability is essential for construction and engineering companies looking to upgrade their safety measures without overhauling their entire system.

In conclusion, the OEM hydraulic single ram blowout preventer is a vital component in ensuring safety and efficiency in high-pressure environments, particularly in the manufacturing and engineering sectors. Understanding its operation and benefits not only enhances safety protocols but also contributes to more reliable and effective operational practices. Investing in such equipment reflects a commitment to not only meet but exceed industry safety standards.

An OEM hydraulic single ram blowout preventer is a specialized device designed to control and prevent the uncontrolled release of fluids and gases during drilling operations. These devices are particularly crucial in oil and gas drilling but have applications in other high-pressure environments as well. The "single ram" refers to its design incorporating a single hydraulic mechanism that can seal the wellbore effectively, stopping any flow of fluid or gas when necessary.

The operation of a blowout preventer is predominantly hydraulic, utilizing pressurized fluids to actuate the device's rams. This hydraulic operation allows for swift engagement in emergency situations, providing a reliable barrier against potential blowouts. Such quick responses are crucial in preventing accidents that can lead to catastrophic events, environmental disasters, or significant operational delays.

Moreover, OEM hydraulic single ram blowout preventers are built to meet specific industry standards for operational efficiency and safety. The manufacturing of these devices often involves advanced engineering techniques and stringent quality controls, ensuring they can withstand high pressures and extreme conditions. This reliability is essential for companies that prioritize both the safety of their personnel and the integrity of their projects.

In addition to their primary function of preventing blowouts, these devices can also assist in pressure control during drilling operations, making them a versatile tool. They are particularly beneficial in environments where the pressures involved can vary significantly, providing a much-needed safety net.

Another significant advantage of using OEM products is that they are typically designed for compatibility with a range of existing equipment. This interoperability is essential for construction and engineering companies looking to upgrade their safety measures without overhauling their entire system.

In conclusion, the OEM hydraulic single ram blowout preventer is a vital component in ensuring safety and efficiency in high-pressure environments, particularly in the manufacturing and engineering sectors. Understanding its operation and benefits not only enhances safety protocols but also contributes to more reliable and effective operational practices. Investing in such equipment reflects a commitment to not only meet but exceed industry safety standards.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China