The Future of Blowout Preventer Control Systems in Agricultural Machinery: Innovations and Impacts

2025-03-07

The Future of Blowout Preventer Control Systems in Agricultural Machinery

Introduction to Blowout Preventer Control Systems

Blowout Preventer (BOP) control systems have long been a critical component in the oil and gas industry, designed to prevent uncontrolled blowouts during drilling operations. However, as agricultural practices evolve, the integration of BOP technology into agricultural machinery emerges as a pivotal advancement. These systems are not merely adaptations; they represent a revolutionary approach to maximizing safety and operational efficiency in farming.

In this article, we will explore the future of BOP control systems in agricultural machinery, focusing on their innovations, applications, and potential to transform the agricultural landscape.

Understanding Blowout Preventer Control Systems

What is a Blowout Preventer?

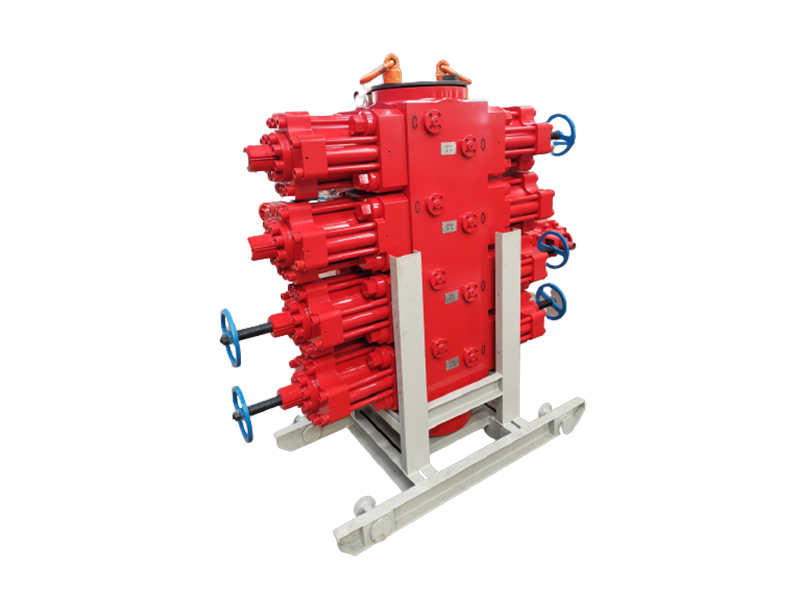

A Blowout Preventer is a specialized device installed on drilling rigs, designed to seal, control, and monitor oil and gas wells to prevent blowouts. In essence, they act as a safety valve, ensuring that pressure is maintained and controlled during drilling operations.

How BOP Control Systems Work

BOP control systems utilize a combination of hydraulic, mechanical, and electronic components to manage the pressure and flow within wells. They can automatically or manually activate to seal the well in case of pressure anomalies, thus preventing hazardous situations.

The Need for BOP in Agricultural Machinery

While the agricultural sector may not seem directly related to the oil and gas industry, the need for safety and precision in farming operations is paramount. Agricultural machinery encounters various pressures, whether from soil compaction, hydraulic systems, or crop management practices. Implementing BOP control systems can lead to safer and more efficient agricultural practices.

Benefits of BOP in Agriculture

1. **Enhanced Safety**: BOP control systems can prevent potential hazards associated with hydraulic system failures on large agricultural machinery, minimizing the risk of accidents.

2. **Operational Efficiency**: By maintaining optimal pressure levels, BOP systems allow agricultural machinery to operate more efficiently, reducing downtime and increasing productivity.

3. **Environmental Protection**: Preventing leaks and blowouts protects the surrounding environment, which is crucial in sustainable farming practices.

Innovations in BOP Control Systems for Agricultural Machinery

Advanced Sensors and Monitoring Technologies

Recent advancements in sensor technology have made it possible to monitor pressure levels and hydraulic functions in real-time. These sensors allow for immediate detection of irregularities, enabling prompt action and preventing potential blowouts.

Integration with IoT and Smart Farming Solutions

With the rise of the Internet of Things (IoT), BOP control systems can now be integrated into smart farming solutions. This connectivity allows farmers to monitor their equipment remotely, analyze data trends, and make informed decisions quickly.

AI and Predictive Maintenance

Artificial intelligence is emerging as a game-changer in predicting when a BOP system might need maintenance. By analyzing historical data, AI algorithms can provide insights into the optimal times for servicing equipment, thereby reducing the risk of unexpected failures.

Applications of BOP Control Systems in Agricultural Machinery

Intractable Soil Management

Agricultural machinery often deals with compacted soil, which can lead to equipment strain and failure. BOP control systems can help manage hydraulic pressures more effectively in machinery like tractors and harvesters, ensuring they operate within safe limits.

Precision Agriculture Techniques

Precision agriculture relies heavily on data and technology to enhance farming practices. BOP systems can be integrated with precision agriculture tools to ensure that equipment operates efficiently and safely, contributing to improved crop yields and sustainable practices.

Water Management Systems

In irrigation and water management, the pressures involved can be significant. BOP technology can help maintain control over water flow, preventing excessive pressure that may lead to system failures or environmental damage.

Future Trends in BOP Control Systems for Agricultural Machinery

Increased Automation

As technology advances, the trend toward automation in agriculture will continue to grow. BOP control systems will likely evolve to include more automated features, allowing for seamless operation without the need for constant human oversight.

Enhanced Data Analytics

The future of agriculture will increasingly rely on data analytics for decision-making. BOP systems will contribute to this by providing valuable data on equipment performance, leading to more informed choices regarding machinery maintenance and operation.

Regulatory Considerations

As the adoption of BOP technology in agriculture increases, so will the regulatory frameworks governing their use. Understanding these regulations is crucial for manufacturers and farmers alike, ensuring that they remain compliant and maintain high safety standards.

Challenges and Considerations for Implementing BOP Systems in Agriculture

While the benefits of BOP control systems in agricultural machinery are considerable, there are challenges to consider.

Cost of Implementation

The initial investment in BOP technology can be significant. Farmers must weigh the costs versus the long-term benefits of increased safety and operational efficiency.

Training and Skill Development

As with any new technology, there is a learning curve. Farmers and equipment operators must be trained on how to use BOP systems effectively to maximize their benefits.

Maintenance and Upkeep

Regular maintenance of BOP systems is essential to ensure their reliability. Developing a robust maintenance plan will be crucial for farmers looking to integrate this technology into their operations.

FAQs About Blowout Preventer Control Systems in Agricultural Machinery

1. What is the primary purpose of a Blowout Preventer in agriculture?

The primary purpose of a Blowout Preventer in agriculture is to ensure safety by controlling hydraulic pressures in agricultural machinery, preventing mechanical failures and accidents.

2. How do BOP systems improve operational efficiency?

BOP systems improve operational efficiency by maintaining optimal pressure levels, reducing downtime, and allowing machinery to operate effectively without interruptions.

3. Are BOP control systems cost-effective for farmers?

While the initial costs may be high, BOP control systems can lead to significant cost savings over time through increased efficiency and reduced accidents.

4. Can BOP systems be integrated with existing agricultural equipment?

Yes, BOP systems can often be retrofitted to existing agricultural equipment, enhancing their safety and performance without the need for new machinery.

5. What role does data analytics play in BOP technology?

Data analytics can be used to monitor and analyze equipment performance, helping farmers make informed decisions regarding maintenance and operation.

Conclusion

The integration of Blowout Preventer control systems in agricultural machinery marks a significant advancement in the industry, focusing on enhancing safety, efficiency, and sustainability. As innovations continue to develop, these systems will not only reshape how farmers operate but also contribute to a more sustainable agricultural future. By embracing these technologies, the agricultural sector can navigate the challenges of modern farming while prioritizing safety and efficiency. As we look ahead, it is clear that the role of BOP systems will be pivotal in shaping the future of agricultural practices.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China