Unveiling the Benefits of Quality Double Ram BOPs in Safety Operations

2025-04-21

Unveiling the Benefits of Quality Double Ram BOPs in Safety Operations

Table of Contents

- 1. Introduction to Double Ram BOPs

- 2. Importance of Safety in Operations

- 3. Design and Functionality of Double Ram BOPs

- 4. Benefits of Quality Double Ram BOPs

- 5. Applications of Double Ram BOPs in Safety Operations

- 6. Maintenance Requirements for Optimal Performance

- 7. Adhering to Industry Standards and Regulations

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Double Ram BOPs

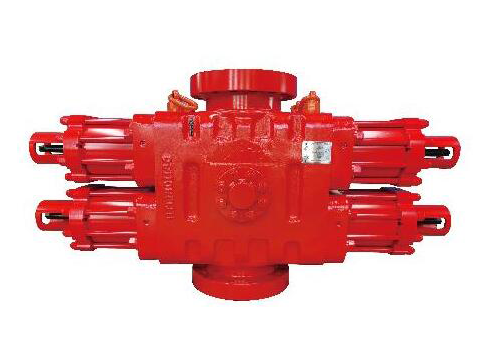

Double Ram Blowout Preventers (BOPs) are critical safety devices used predominantly in drilling operations. Their primary function is to prevent the uncontrolled release of fluids and gases during drilling activities. By employing a dual-ram design, these BOPs enhance the reliability and effectiveness of safety measures in high-pressure environments. Understanding the mechanics and advantages of quality Double Ram BOPs is essential for ensuring operational safety and environmental protection.

2. Importance of Safety in Operations

Safety in industrial operations cannot be overstated. In sectors such as oil and gas, mining, and construction, the risks associated with pressure control and fluid management are significant. Implementing robust safety mechanisms like Double Ram BOPs not only protects personnel but also safeguards the environment. By mitigating risks and enhancing operational integrity, companies can prevent catastrophic incidents and foster a culture of safety.

3. Design and Functionality of Double Ram BOPs

The design of Double Ram BOPs features two independent rams that can seal the wellbore. This design allows for greater control during drilling operations, effectively managing pressure fluctuations. The rams can operate individually, offering versatility in handling different well conditions. Typically constructed from high-strength materials, quality Double Ram BOPs are engineered to withstand extreme pressures and temperatures, ensuring durability and reliability.

Key Components of Double Ram BOPs

The key components of Double Ram BOPs include:

- **Rams:** These are the mechanical seals that close around the drill pipe or seal off the wellbore.

- **Bonnet:** Houses the rams and provides the necessary support structure.

- **Hydraulic System:** Powers the operation of the rams, allowing for rapid engagement and disengagement.

- **Control Systems:** Enable operators to manage the functionality of the BOPs remotely, ensuring quick response times.

4. Benefits of Quality Double Ram BOPs

Investing in quality Double Ram BOPs offers numerous advantages that enhance safety and operational efficiency.

4.1 Enhanced Safety Measures

Quality Double Ram BOPs provide a superior safety net during drilling, significantly reducing the likelihood of blowouts. By effectively sealing the wellbore, they prevent the uncontrolled release of hazardous materials, ensuring the safety of the crew and the environment. Their rapid response capabilities allow for immediate action in emergency situations, further enhancing safety protocols.

4.2 Reduced Environmental Risks

Environmental protection is a major concern in industrial operations. Quality Double Ram BOPs minimize the risk of spills and leaks, reducing the potential for environmental contamination. With stringent regulations governing environmental safety, having reliable BOPs in place can help companies remain compliant while also protecting natural resources.

4.3 Cost Efficiency in Operations

Though the initial investment in quality Double Ram BOPs may be significant, the long-term savings they offer cannot be overlooked. By preventing blowouts and the associated costs of cleanup and regulatory fines, these systems can reduce overall operational expenses. Additionally, fewer interruptions in drilling operations lead to greater productivity and efficiency.

5. Applications of Double Ram BOPs in Safety Operations

Double Ram BOPs find applications in various industries, including:

- **Oil and Gas Exploration:** Essential for managing high-pressure wells.

- **Geothermal Energy Production:** Used to control fluids during drilling.

- **Mining Operations:** Helps manage the risks associated with underground drilling activities.

Each application demonstrates the versatility and importance of these devices in maintaining safe operating conditions.

6. Maintenance Requirements for Optimal Performance

To ensure optimal performance, regular maintenance of Double Ram BOPs is crucial. This includes:

- **Routine Inspections:** Checking for wear and tear, and ensuring all components are functioning properly.

- **Hydraulic System Maintenance:** Regularly servicing the hydraulic system to prevent malfunctions.

- **Testing Procedures:** Conducting pressure tests to verify the integrity of the seals.

Adhering to a strict maintenance schedule can prolong the lifespan of BOPs and enhance their reliability.

7. Adhering to Industry Standards and Regulations

Compliance with industry standards and regulations is vital for safety operations. Organizations such as the American Petroleum Institute (API) outline specific requirements for BOPs, ensuring they meet safety and performance benchmarks. Companies must stay informed about these standards and incorporate them into their operational practices to mitigate risks.

8. Frequently Asked Questions

What is the primary function of a Double Ram BOP?

The primary function is to seal the wellbore and prevent uncontrolled releases of fluids and gases during drilling operations.

How often should Double Ram BOPs be maintained?

Regular maintenance is essential, typically every 6 to 12 months, depending on usage and operational conditions.

What materials are used in the construction of Double Ram BOPs?

They are commonly made from high-strength steel alloys to withstand extreme pressures and harsh environments.

Why are Double Ram BOPs preferred over other types?

Their dual-ram design provides enhanced sealing capabilities and greater control in high-pressure scenarios.

What are the consequences of not using quality BOPs?

Not using quality BOPs can lead to blowouts, environmental disasters, and significant financial losses due to downtime and clean-up efforts.

9. Conclusion

Quality Double Ram BOPs are indispensable tools in ensuring safety and efficiency in various operational settings. Their advanced design, coupled with substantial benefits such as enhanced safety, reduced environmental risks, and cost efficiency, makes them a vital investment for companies involved in high-pressure drilling activities. By adhering to maintenance protocols and industry standards, organizations can maximize the utility of their Double Ram BOPs, ultimately contributing to safer and more sustainable operations.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China