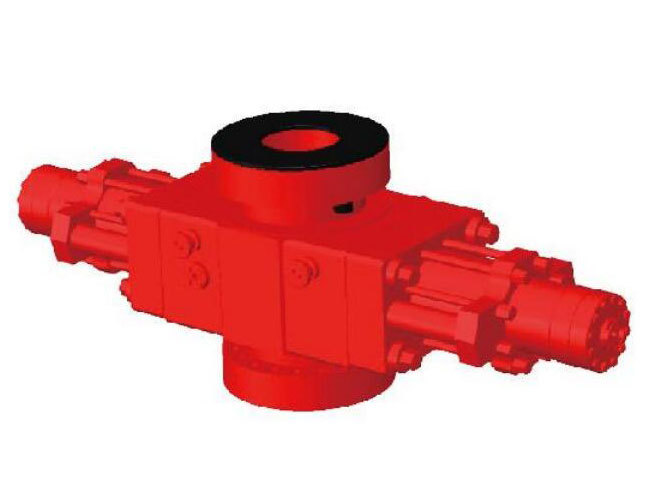

Understanding Hydraulic Single Ram BOP: A Key Component in Safety and Protection

2025-04-26

Hydraulic Single Ram Blowout Preventers (BOP) serve as essential components in the safety and protection industry, specifically within the realm of operational safety products. These devices are crucial for preventing uncontrolled releases of fluids and gases during drilling operations, thereby safeguarding personnel, equipment, and the environment.

A Hydraulic Single Ram BOP works by utilizing hydraulic pressure to close a single ram that seals the wellbore in the event of a blowout. This mechanism is vital in high-pressure environments where there is a risk of hydrocarbon release. The design allows for quick activation, ensuring that any unexpected surge of pressure can be contained almost instantaneously. Unlike other types of preventers, the single ram design minimizes mechanical complexity, making it a reliable choice for various drilling applications.

One of the primary advantages of using a Hydraulic Single Ram BOP is its ability to maintain well control. In an industry where the stakes are high, and the consequences of a blowout can lead to catastrophic events, the importance of efficient pressure containment cannot be overstated. The single ram feature provides sufficient sealing capability while simplifying maintenance and operational procedures.

In addition to well control, these BOP systems also contribute to the overall safety culture within organizations. When workers know that robust protective measures are in place, it enhances their confidence and focus on the tasks at hand. This aspect is particularly important in industries such as oil and gas, where safety protocols are paramount.

Moreover, the versatility of Hydraulic Single Ram BOP systems allows them to be employed in various environments, from offshore drilling platforms to onshore operations. Their adaptability to different conditions, including extreme temperatures and pressures, makes them indispensable tools in modern drilling operations.

It is also crucial to consider the regular maintenance and inspections required for these systems. While Hydraulic Single Ram BOPs are designed for durability and efficiency, routine checks ensure that they function correctly under pressure. Organizations are encouraged to implement comprehensive monitoring programs to maintain operational readiness and compliance with safety regulations.

In summary, the Hydraulic Single Ram BOP is a pivotal element in the safety and protection industry. Its ability to provide reliable well control, enhance safety culture, and adapt to diverse operational environments underscores its significance. As industries continue to prioritize safety in their operations, understanding the role of such preventive equipment becomes essential for all stakeholders involved.

A Hydraulic Single Ram BOP works by utilizing hydraulic pressure to close a single ram that seals the wellbore in the event of a blowout. This mechanism is vital in high-pressure environments where there is a risk of hydrocarbon release. The design allows for quick activation, ensuring that any unexpected surge of pressure can be contained almost instantaneously. Unlike other types of preventers, the single ram design minimizes mechanical complexity, making it a reliable choice for various drilling applications.

One of the primary advantages of using a Hydraulic Single Ram BOP is its ability to maintain well control. In an industry where the stakes are high, and the consequences of a blowout can lead to catastrophic events, the importance of efficient pressure containment cannot be overstated. The single ram feature provides sufficient sealing capability while simplifying maintenance and operational procedures.

In addition to well control, these BOP systems also contribute to the overall safety culture within organizations. When workers know that robust protective measures are in place, it enhances their confidence and focus on the tasks at hand. This aspect is particularly important in industries such as oil and gas, where safety protocols are paramount.

Moreover, the versatility of Hydraulic Single Ram BOP systems allows them to be employed in various environments, from offshore drilling platforms to onshore operations. Their adaptability to different conditions, including extreme temperatures and pressures, makes them indispensable tools in modern drilling operations.

It is also crucial to consider the regular maintenance and inspections required for these systems. While Hydraulic Single Ram BOPs are designed for durability and efficiency, routine checks ensure that they function correctly under pressure. Organizations are encouraged to implement comprehensive monitoring programs to maintain operational readiness and compliance with safety regulations.

In summary, the Hydraulic Single Ram BOP is a pivotal element in the safety and protection industry. Its ability to provide reliable well control, enhance safety culture, and adapt to diverse operational environments underscores its significance. As industries continue to prioritize safety in their operations, understanding the role of such preventive equipment becomes essential for all stakeholders involved.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China