Innovations in Four-Ram Blowout Preventers for Enhanced Safety: Revolutionizing Oil and Gas Operations

2025-05-09

Innovations in Four-Ram Blowout Preventers for Enhanced Safety

Table of Contents

- Introduction to Four-Ram Blowout Preventers

- The Importance of Blowout Preventers in the Oil and Gas Industry

- Key Innovations in Four-Ram Blowout Preventers

- Case Studies of Successful Implementation

- Best Practices for Using Four-Ram Blowout Preventers

- Regulatory Standards and Compliance

- Future Trends in Blowout Prevention Technology

- Frequently Asked Questions

- Conclusion

Introduction to Four-Ram Blowout Preventers

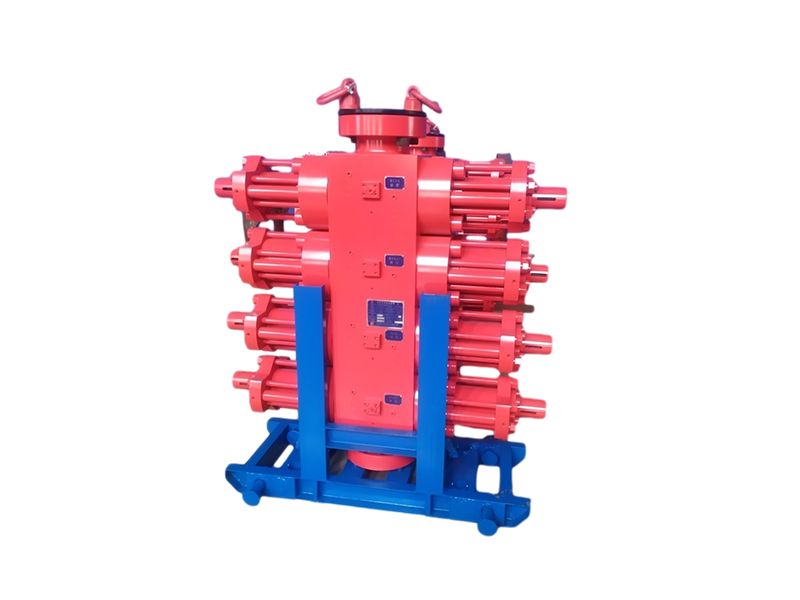

Four-ram blowout preventers (BOPs) are critical safety devices used in drilling operations within the oil and gas industry. These devices are designed to prevent the uncontrolled release of crude oil or natural gas from a well during drilling activities. The four-ram configuration allows for a higher sealing capacity and improved reliability, making them essential for maintaining safety standards.

In an industry where the stakes are high, and the consequences of a blowout can be catastrophic, innovations in BOP technology have become paramount. This article explores the latest advancements in four-ram blowout preventers and how they enhance safety protocols in drilling operations.

The Importance of Blowout Preventers in the Oil and Gas Industry

Blowout preventers are vital for safeguarding both personnel and the environment. They provide a first line of defense against blowouts, which can occur due to sudden changes in pressure or unexpected geological formations. A successful blowout preventer can contain or redirect uncontrollable pressures, significantly reducing the risk of explosions, spills, and other hazardous incidents.

In recent years, the industry has seen an increased focus on the development of more reliable and efficient BOP systems. Regulatory bodies and oil companies alike recognize the necessity of investing in advanced blowout prevention technologies to ensure operational safety and environmental protection.

Key Innovations in Four-Ram Blowout Preventers

The evolution of four-ram blowout preventers has been marked by remarkable innovations that address both performance and safety. The following sections highlight the most significant advancements in this field.

Advanced Materials and Design

Recent innovations in materials science have led to the development of more durable and resilient components for four-ram BOPs. High-strength alloys and composite materials are now standard, offering improved resistance to corrosion, high temperatures, and extreme pressures.

Additionally, the design of four-ram BOPs has become more streamlined, enhancing their efficiency. Modern designs incorporate features such as:

- **Improved sealing surfaces**: Enhanced sealing technology ensures tighter seals, reducing the likelihood of leaks during operation.

- **Modular design**: This allows for easier maintenance and quicker replacements of components, minimizing downtime during drilling operations.

Smart Technology and Integration

The integration of smart technology into blowout preventers is a game-changer for the oil and gas industry. These advancements include:

- **Real-time monitoring**: Advanced sensors and IoT technology enable continuous monitoring of BOP performance, providing operators with crucial data to make informed decisions during drilling operations.

- **Predictive maintenance**: By analyzing data collected from sensors, companies can predict potential failures and schedule maintenance before issues arise, further enhancing safety.

Such smart technologies not only optimize performance but also reduce the chances of human error, ensuring that blowout preventers function correctly when needed.

Enhanced Maintenance and Durability

Innovations in maintenance practices are also pivotal in the evolution of four-ram BOPs. Companies are adopting condition-based maintenance strategies, which prioritize maintenance based on the actual condition of the equipment rather than fixed schedules.

Enhanced durability features, such as:

- **Corrosion-resistant coatings**: These coatings extend the lifespan of BOP components, reducing the frequency of replacements.

- **Self-diagnostic capabilities**: BOPs equipped with these features can alert operators about potential issues, allowing for timely interventions.

Case Studies of Successful Implementation

Several companies have successfully implemented innovative four-ram blowout preventers, demonstrating the effectiveness of these technologies in real-world applications.

One notable case involved an offshore drilling operation that incorporated advanced BOP technology equipped with real-time monitoring systems. During drilling, the system detected abnormal pressure changes and alerted the crew in time to take preventative actions. This proactive approach prevented a potential blowout, ensuring the safety of personnel and the environment.

Another example can be seen in a land-based drilling operation that utilized a modular BOP design. The company reported a significant reduction in downtime due to easier maintenance and quicker component replacements, resulting in increased overall productivity and enhanced safety.

Best Practices for Using Four-Ram Blowout Preventers

To fully benefit from the innovations in four-ram blowout preventers, companies must adhere to best practices that ensure their effective operation. Here are some critical recommendations:

- **Regular training for personnel**: Continuous education and training for staff on the latest BOP technologies and procedures are essential for maintaining safety standards.

- **Routine inspections and maintenance**: Implementing a strict schedule for inspections and maintenance can significantly reduce the chances of equipment failure during operations.

- **Data analysis and performance reviews**: Utilizing data from monitoring systems to analyze BOP performance helps identify trends and areas for improvement.

Regulatory Standards and Compliance

Compliance with regulatory standards is vital for the safe operation of four-ram blowout preventers. Organizations such as the American Petroleum Institute (API) and the Bureau of Safety and Environmental Enforcement (BSEE) set guidelines that must be followed to ensure safety and environmental protection.

Staying updated with changing regulations and ensuring that BOP systems meet or exceed these standards is crucial for any company engaged in drilling operations. Regular audits and assessments can help maintain compliance and encourage continuous improvement.

Future Trends in Blowout Prevention Technology

As technology continues to advance, the future of four-ram blowout preventers looks promising. Emerging trends include:

- **Artificial Intelligence (AI) Integration**: The application of AI in data analysis and decision-making processes could lead to more effective and safer drilling operations.

- **Increased Automation**: Automation of BOP functions may reduce the reliance on human intervention, lowering the risk of errors during critical operations.

- **Sustainable Technologies**: The push for environmentally friendly technologies will likely influence future designs of blowout preventers, focusing on reducing environmental impact while maintaining safety.

Frequently Asked Questions

1. What is a blowout preventer (BOP)?

A blowout preventer is a large valve or series of valves installed on a well to prevent the uncontrolled release of oil or gas during drilling operations.

2. How does a four-ram BOP differ from other types of BOPs?

Four-ram BOPs utilize four rams to provide a higher sealing capacity and improved reliability compared to other types of BOPs, such as two-ram systems.

3. What are the main benefits of advanced materials in BOP design?

Advanced materials improve the durability, resistance to corrosion, and overall performance of blowout preventers, enhancing their reliability in extreme conditions.

4. How does smart technology improve blowout preventers?

Smart technology allows for real-time monitoring, predictive maintenance, and data analysis, significantly improving the operational efficiency and safety of BOPs.

5. What are the key regulatory standards for blowout preventers?

Key regulatory standards include guidelines set by organizations such as the American Petroleum Institute (API) and the Bureau of Safety and Environmental Enforcement (BSEE), which govern the design, operation, and maintenance of BOPs.

Conclusion

Innovations in four-ram blowout preventers are reshaping the safety landscape of the oil and gas industry. Through advancements in materials, design, and smart technologies, these critical devices have become more reliable and efficient in preventing blowouts. By adhering to best practices and compliance with regulatory standards, companies can ensure the safety of personnel and the environment. As we look toward the future, continued innovation and a focus on sustainable practices will be essential in maintaining safe and efficient drilling operations.

PREVIOUS:

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China