How Sucker Rod Annular BOPs Enhance Job Site Safety: The Ultimate Guide

2025-05-01

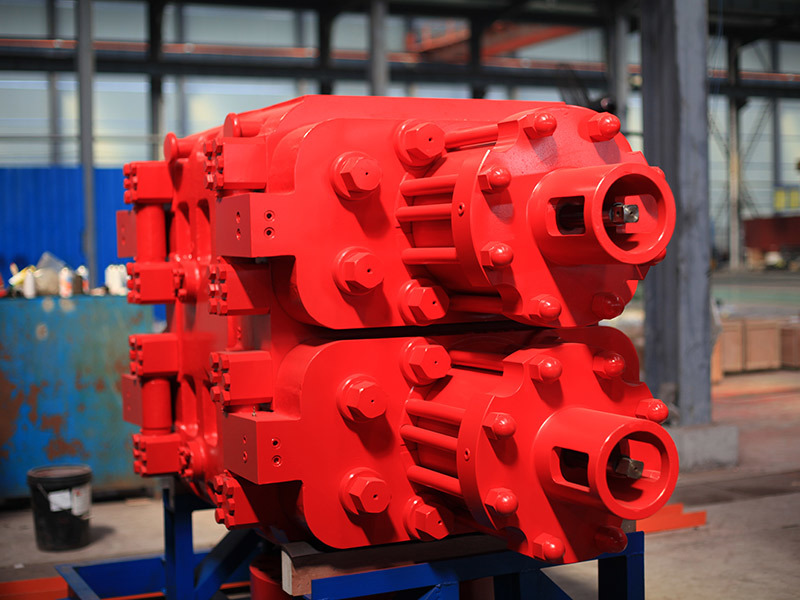

How Sucker Rod Annular BOPs Enhance Job Site Safety

Introduction to Sucker Rod Annular BOPs

Sucker Rod Annular Blowout Preventers (BOPs) are critical components in maintaining safety at job sites, particularly in the oil and gas industry. These devices are designed to control well pressure, preventing blowouts that could lead to catastrophic accidents. Understanding how these systems work and their impact on safety can help organizations implement better safety measures and protect their workforce.

Understanding Blowout Preventers (BOPs)

Blowout Preventers are specialized valves installed on wells to prevent the uncontrolled release of crude oil or natural gas. They play a vital role in the safety infrastructure of drilling and production operations.

Types of Blowout Preventers

There are several types of BOPs, including:

- **Annular BOPs**: Provide a seal around the drill pipe, allowing for flexibility in handling various pipe sizes.

- **Ram BOPs**: Feature two opposing rams that can quickly seal off the wellbore.

Sucker Rod Annular BOPs are a hybrid solution that combines the advantages of both types, ensuring enhanced safety and control.

The Functionality of Sucker Rod Annular BOPs

Sucker Rod Annular BOPs operate by creating a barrier that can withstand high-pressure conditions. When pressure builds up within the well, these BOPs can instantly seal the annular space, preventing blowouts.

Key Features of Sucker Rod Annular BOPs

- **Versatile Sealing**: They can accommodate different sizes of sucker rods and casing pipes, which makes them suitable for various drilling conditions.

- **Automatic Activation**: Many of these BOPs are equipped with automatic activation features that engage during a pressure surge, reducing human error.

- **Durability**: Constructed from high-strength materials, these BOPs withstand extreme conditions, ensuring reliability.

Importance of Sucker Rod Annular BOPs in Job Site Safety

Ensuring that job sites are safe for workers is paramount. Sucker Rod Annular BOPs contribute to this safety in several critical ways.

Preventing Blowouts

The primary function of any BOP, including sucker rod annular designs, is to prevent blowouts. A blowout can release hazardous materials, leading to dangerous situations for workers. By ensuring pressure control, these BOPs protect personnel and equipment.

Enhancing Emergency Response

In the event of an emergency, the quick sealing capability of sucker rod annular BOPs allows for faster response times. This efficiency can be the difference between a manageable situation and a full-blown crisis.

Best Practices for Implementing Sucker Rod Annular BOPs

To maximize the safety aspects of sucker rod annular BOPs, organizations should adopt certain best practices.

Regular Maintenance and Inspections

Routine checks and maintenance of BOPs are essential to ensure they function effectively. Regular inspections help identify any wear or damage, allowing for timely repairs.

Training Personnel

All personnel should be adequately trained on the operation and maintenance of sucker rod annular BOPs. This training should include emergency response protocols to prepare workers for potential blowout situations.

Regulatory Standards and Compliance

Compliance with industry regulations is crucial for the safe operation of sucker rod annular BOPs. Organizations must stay updated with OSHA regulations and API standards, ensuring that their equipment meets all safety requirements.

Understanding OSHA Regulations

The Occupational Safety and Health Administration (OSHA) has specific guidelines regarding blowout prevention and emergency response. Familiarity with these regulations ensures that organizations are compliant and prioritize worker safety.

API Standards for BOPs

The American Petroleum Institute (API) sets forth standards for the design and maintenance of BOPs. Adhering to these standards ensures that sucker rod annular BOPs are built to withstand industry challenges.

Future Innovations in BOP Technology

As technology advances, the design and functionality of sucker rod annular BOPs will continue to evolve. Innovations may include enhanced materials, smarter control systems, and improved safety mechanisms.

Smart BOP Systems

The integration of smart technology into BOP systems allows for real-time monitoring and alerts. These systems can notify operators of any irregularities in well pressure, improving response times and reducing the likelihood of accidents.

Real-World Case Studies: Success Stories of Enhanced Safety

Several case studies exemplify the effectiveness of sucker rod annular BOPs in enhancing job site safety.

Case Study 1: A Successful Implementation in Offshore Drilling

In an offshore drilling operation, the integration of sucker rod annular BOPs led to a significant decrease in blowout incidents. Following the introduction of these systems, the site reported improved safety records and enhanced emergency response capabilities.

Case Study 2: Onshore Operations and Reduced Risks

An onshore drilling company adopted sucker rod annular BOPs, leading to improved safety protocols and reduced risks. Regular training and maintenance contributed to their success, demonstrating the importance of proactive safety measures.

Frequently Asked Questions (FAQs)

1. What is the primary function of a sucker rod annular BOP?

The primary function is to control well pressure and prevent blowouts during drilling operations.

2. How does a sucker rod annular BOP differ from other BOP types?

Sucker rod annular BOPs provide versatile sealing for various pipe sizes, while other types may only operate effectively within specific dimensions.

3. What are the critical maintenance practices for sucker rod annular BOPs?

Regular inspections, routine maintenance, and employee training are essential for optimal performance.

4. Are there any new technologies emerging for BOPs?

Yes, smart BOP systems that offer real-time monitoring and alerts are currently being developed to enhance safety further.

5. How can organizations ensure compliance with safety regulations regarding BOPs?

Staying informed about OSHA and API standards, conducting regular training, and maintaining equipment can ensure compliance.

Conclusion

Sucker Rod Annular BOPs play a vital role in enhancing job site safety by preventing blowouts and ensuring rapid response measures are in place. By understanding their functionality, adhering to best practices, and embracing future innovations, companies can significantly improve workplace safety. Ensuring compliance with regulatory standards is not just beneficial for the organization but essential for the well-being of every worker on site. As technology evolves, the capabilities of sucker rod annular BOPs will likely expand, further solidifying their importance in the safety landscape of the oil and gas industry.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China