Understanding Sucker Rod Annular BOP: Key Insights for Safety and Protection

2025-05-02

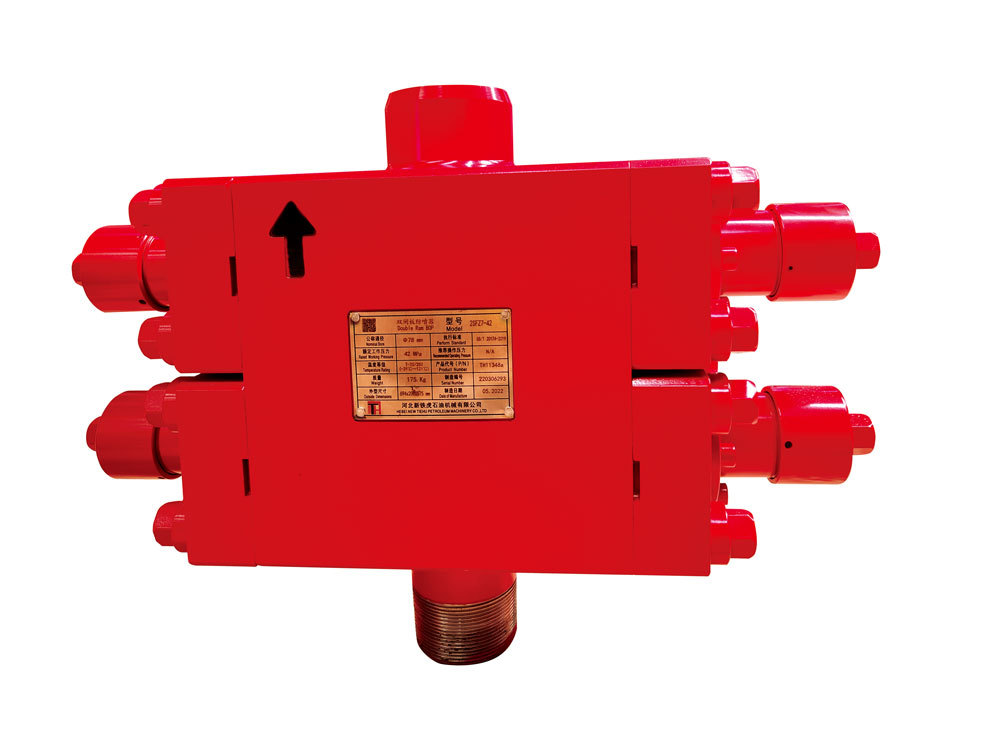

The Sucker Rod Annular Blowout Preventer (BOP) is a critical safety device in the oil and gas industry, specifically designed to manage well pressures and prevent uncontrolled releases of crude oil or natural gas, commonly referred to as blowouts. Understanding how this equipment functions is essential for professionals in the safety and protection sector, as it plays a pivotal role in safeguarding personnel, equipment, and the environment.

Sucker rods are long, slender rods used in pumping oil from wells, and when combined with an annular BOP, they enable operators to securely seal off a wellbore during drilling or servicing operations. The annular design allows for flexibility, accommodating varying sizes of drill pipes and sucker rods while providing a reliable seal against high-pressure fluids. This adaptability is crucial in maintaining operational integrity and ensuring that any pressure buildup within the well is effectively contained.

One of the primary functions of the Sucker Rod Annular BOP is its ability to react swiftly to sudden pressure changes. In the event of an unexpected surge, the BOP can quickly close off the wellbore, preventing the escape of hazardous materials. This feature is vital not only for the safety of the workforce but also for protecting the environment from potential contamination.

Moreover, the installation and maintenance of a Sucker Rod Annular BOP require adherence to stringent industry standards and safety protocols. Regular inspections and testing are essential to ensure that the device remains operational and effective in emergencies. Personnel should be trained to understand the mechanisms of the BOP, including how to operate it in various scenarios to maximize safety and efficiency.

In addition to their primary function of preventing blowouts, Sucker Rod Annular BOPs also contribute to overall operational efficiency. By controlling well pressure during drilling operations, they minimize the risk of costly downtimes and potential damage to drilling equipment. This efficiency translates to economic benefits for operators, making the investment in high-quality BOP systems worthwhile.

In conclusion, the Sucker Rod Annular BOP is an indispensable piece of safety equipment in the oil and gas industry. Its ability to prevent blowouts and manage well pressures not only protects lives but also preserves the integrity of the environment. Understanding the operation and importance of this device is crucial for professionals in safety and protective equipment, ensuring that they can effectively mitigate risks and enhance the safety of their operations.

Sucker rods are long, slender rods used in pumping oil from wells, and when combined with an annular BOP, they enable operators to securely seal off a wellbore during drilling or servicing operations. The annular design allows for flexibility, accommodating varying sizes of drill pipes and sucker rods while providing a reliable seal against high-pressure fluids. This adaptability is crucial in maintaining operational integrity and ensuring that any pressure buildup within the well is effectively contained.

One of the primary functions of the Sucker Rod Annular BOP is its ability to react swiftly to sudden pressure changes. In the event of an unexpected surge, the BOP can quickly close off the wellbore, preventing the escape of hazardous materials. This feature is vital not only for the safety of the workforce but also for protecting the environment from potential contamination.

Moreover, the installation and maintenance of a Sucker Rod Annular BOP require adherence to stringent industry standards and safety protocols. Regular inspections and testing are essential to ensure that the device remains operational and effective in emergencies. Personnel should be trained to understand the mechanisms of the BOP, including how to operate it in various scenarios to maximize safety and efficiency.

In addition to their primary function of preventing blowouts, Sucker Rod Annular BOPs also contribute to overall operational efficiency. By controlling well pressure during drilling operations, they minimize the risk of costly downtimes and potential damage to drilling equipment. This efficiency translates to economic benefits for operators, making the investment in high-quality BOP systems worthwhile.

In conclusion, the Sucker Rod Annular BOP is an indispensable piece of safety equipment in the oil and gas industry. Its ability to prevent blowouts and manage well pressures not only protects lives but also preserves the integrity of the environment. Understanding the operation and importance of this device is crucial for professionals in safety and protective equipment, ensuring that they can effectively mitigate risks and enhance the safety of their operations.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China