Essential Insights on In Stock Hydraulic Double Ram BOP: A Comprehensive Guide

2025-05-06

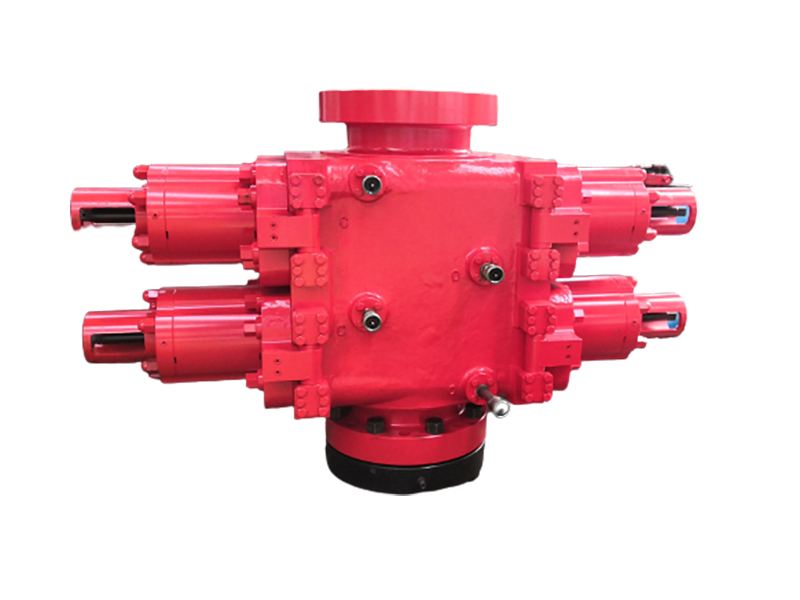

Hydraulic Double Ram Blowout Preventers (BOP) are crucial components in the safety and operational protocols of drilling activities. These devices are designed to prevent uncontrolled releases of crude oil or natural gas from a well during drilling operations. A blowout is a significant hazard in the oil and gas industry, and the use of effective BOP systems is essential to safeguard personnel and equipment.

The hydraulic double ram BOP features two rams that can seal off the wellbore in the event of a blowout. This dual-ramp design provides added reliability and strength, making it an industry-preferred choice for well control measures. The two rams can be operated independently, allowing for quick and efficient response in emergency situations. This capability is fundamental in maintaining well integrity and ensuring that any potential risks are managed effectively.

One of the key advantages of the hydraulic double ram BOP is its versatility. It can be utilized in various drilling environments, including offshore and onshore operations. Given the demanding nature of these environments, the robust design of hydraulic BOPs ensures they can withstand high pressures and extreme conditions. Their reliable performance is vital in preventing blowouts that could lead to catastrophic accidents, environmental disasters, and significant financial losses.

Maintaining a well-functioning hydraulic double ram BOP is critical. Regular inspections and maintenance checks are necessary to ensure that all components are operating effectively. Any signs of wear and tear or malfunction should be promptly addressed to prevent accidents. The industry standards dictate that operators should follow a strict maintenance schedule, and training personnel on the proper use and upkeep of BOP systems is essential to maintain safety protocols.

In addition to their protective function, hydraulic double ram BOPs also play a role in operational efficiency. By preventing blowouts, these devices help to minimize downtime in drilling operations, thus ensuring that project timelines are adhered to. This aspect is particularly important in the competitive landscape of the oil and gas industry, where efficiency translates to cost savings.

Overall, understanding the functionality and significance of in-stock hydraulic double ram BOP is paramount for any organization involved in drilling operations. These devices are not merely safety equipment; they are integral to the overall success and safety of drilling activities. By prioritizing the use of reliable BOP systems, companies can enhance their operational efficiency while ensuring the safety of their personnel and the environment.

The hydraulic double ram BOP features two rams that can seal off the wellbore in the event of a blowout. This dual-ramp design provides added reliability and strength, making it an industry-preferred choice for well control measures. The two rams can be operated independently, allowing for quick and efficient response in emergency situations. This capability is fundamental in maintaining well integrity and ensuring that any potential risks are managed effectively.

One of the key advantages of the hydraulic double ram BOP is its versatility. It can be utilized in various drilling environments, including offshore and onshore operations. Given the demanding nature of these environments, the robust design of hydraulic BOPs ensures they can withstand high pressures and extreme conditions. Their reliable performance is vital in preventing blowouts that could lead to catastrophic accidents, environmental disasters, and significant financial losses.

Maintaining a well-functioning hydraulic double ram BOP is critical. Regular inspections and maintenance checks are necessary to ensure that all components are operating effectively. Any signs of wear and tear or malfunction should be promptly addressed to prevent accidents. The industry standards dictate that operators should follow a strict maintenance schedule, and training personnel on the proper use and upkeep of BOP systems is essential to maintain safety protocols.

In addition to their protective function, hydraulic double ram BOPs also play a role in operational efficiency. By preventing blowouts, these devices help to minimize downtime in drilling operations, thus ensuring that project timelines are adhered to. This aspect is particularly important in the competitive landscape of the oil and gas industry, where efficiency translates to cost savings.

Overall, understanding the functionality and significance of in-stock hydraulic double ram BOP is paramount for any organization involved in drilling operations. These devices are not merely safety equipment; they are integral to the overall success and safety of drilling activities. By prioritizing the use of reliable BOP systems, companies can enhance their operational efficiency while ensuring the safety of their personnel and the environment.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China