Understanding the Importance of the Newest Four-Ram Blowout Preventer

2025-05-07

Understanding the Importance of the Newest Four-Ram Blowout Preventer

Table of Contents

- 1. Introduction to Blowout Preventers

- 2. What is a Four-Ram Blowout Preventer?

- 3. Advantages of Four-Ram Blowout Preventers

- 4. How Four-Ram Blowout Preventers Work

- 5. Latest Technological Advancements in Four-Ram Blowout Preventers

- 6. Applications in the Drilling Industry

- 7. Regulatory Compliance and Industry Standards

- 8. Future Trends in Blowout Prevention Technology

- 9. FAQs

- 10. Conclusion

1. Introduction to Blowout Preventers

In the oil and gas industry, **safety** is of utmost importance, especially during drilling operations. The risk of a blowout, which is an uncontrolled release of crude oil or natural gas, can lead to catastrophic consequences. This is where Blowout Preventers (BOPs) come into play. These essential devices are designed to seal, control, and monitor oil and gas wells, preventing blowouts and ensuring the safety of personnel, equipment, and the environment.

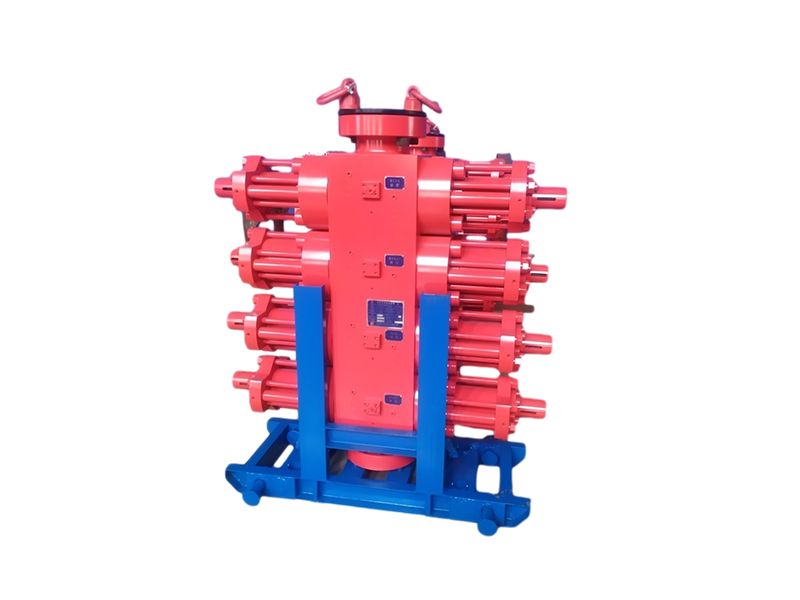

Among the various types of BOPs, the **Four-Ram Blowout Preventer** stands out due to its advanced design and proven effectiveness. This article delves into the significance of the newest Four-Ram Blowout Preventer, highlighting its features, advantages, and essential role in modern drilling operations.

2. What is a Four-Ram Blowout Preventer?

A **Four-Ram Blowout Preventer** is a specialized type of BOP that utilizes four rams to seal the wellbore. Each ram is designed to close off the well in the event of a pressure surge, effectively preventing blowouts. The rams are typically operated hydraulically, allowing for rapid deployment and retraction.

Four-Ram BOPs are designed for both **stacked** and **inline** configurations, providing operational flexibility to accommodate various drilling scenarios. These devices offer superior sealing capabilities compared to traditional two-ram models, making them increasingly popular in the industry.

3. Advantages of Four-Ram Blowout Preventers

The adoption of Four-Ram Blowout Preventers offers several notable advantages, making them a preferred choice for drilling companies worldwide.

3.1 Enhanced Safety Features

One of the primary advantages of the Four-Ram BOP is its **enhanced safety features**. The four independent rams provide redundancy, ensuring that even if one ram fails, others can still maintain pressure control. This multi-layered approach significantly reduces the risk of blowouts, thereby protecting personnel and the environment.

Moreover, modern Four-Ram BOPs are equipped with advanced monitoring systems that provide real-time data on pressure levels, enabling operators to respond swiftly to potential threats.

3.2 Increased Efficiency and Performance

In addition to safety, Four-Ram Blowout Preventers are designed for **increased efficiency and performance**. The hydraulic systems used in these devices allow for quick response times, enabling operators to react to changes in well pressure almost instantaneously. This efficiency translates into minimized drilling downtime, ensuring that operations remain on schedule and within budget.

The advanced design of Four-Ram BOPs also contributes to better sealing capabilities, allowing them to handle higher pressure ranges than their two-ram counterparts. This makes them ideal for deepwater and high-pressure drilling applications.

4. How Four-Ram Blowout Preventers Work

Understanding the operation of a Four-Ram Blowout Preventer requires a look at its core components and functionality. At its heart, the BOP consists of four hydraulic rams that can be activated to seal the wellbore.

1. **Hydraulic Activation**: The rams are operated through a hydraulic system, which can be activated remotely or on-site. When a pressure surge is detected, the operator engages the hydraulic system, pushing the rams into position.

2. **Sealing Mechanism**: Once activated, the rams close off the wellbore, creating a seal that prevents any fluid or gas from escaping. This prevents a blowout and allows for safe drilling operations to continue.

3. **Monitoring Systems**: Modern Four-Ram BOPs are equipped with sensors that monitor pressure levels within the well. This data is transmitted to the drilling control system, providing operators with real-time information about the well's status.

5. Latest Technological Advancements in Four-Ram Blowout Preventers

The field of blowout prevention technology is continuously evolving. The latest advancements in Four-Ram Blowout Preventers focus on improving safety, efficiency, and operational reliability.

1. **Smart Technology Integration**: Many manufacturers are incorporating smart technology into Four-Ram BOPs. This includes predictive maintenance systems that monitor the health of the BOP and alert operators to potential issues before they become critical.

2. **Improved Materials**: Advances in materials science have led to the development of more durable seals and components. These materials withstand extreme pressures and harsh environmental conditions, extending the lifespan of the BOP and reducing maintenance costs.

3. **Enhanced Control Systems**: Newer control systems offer greater precision in operating the BOP. These systems allow for smoother and more reliable activation of the rams, further ensuring the safety of drilling operations.

6. Applications in the Drilling Industry

The Four-Ram Blowout Preventer is widely utilized across various segments of the drilling industry, including both offshore and onshore applications.

6.1 Offshore Drilling

In offshore drilling operations, where the potential for blowouts is significantly elevated due to environmental factors, Four-Ram Blowout Preventers play a crucial role. The advanced sealing capabilities of these BOPs are essential in deepwater drilling, where high pressures are common.

The use of Four-Ram BOPs in offshore rigs ensures that drilling operations can be conducted safely, minimizing the risk of environmental disasters and protecting marine ecosystems.

6.2 Onshore Drilling

Onshore drilling operations also benefit from the capabilities of Four-Ram Blowout Preventers. These BOPs are particularly valuable in high-pressure environments, where traditional BOPs may not provide sufficient protection.

The efficiency and reliability of Four-Ram BOPs enable onshore drilling companies to conduct operations with greater confidence, ensuring safety and compliance with industry standards.

7. Regulatory Compliance and Industry Standards

As safety regulations become more stringent, the importance of compliance in the drilling industry cannot be overstated. Four-Ram Blowout Preventers must meet various industry standards to ensure their effectiveness and safety.

1. **API Standards**: The American Petroleum Institute (API) sets forth standards for BOPs, outlining testing requirements, materials, and performance expectations. Four-Ram BOPs must comply with these standards to ensure reliability.

2. **International Regulations**: In addition to domestic standards, international regulations also govern the use of BOPs in offshore and onshore drilling operations. Compliance with these regulations is critical for companies operating in multiple jurisdictions.

3. **Safety Certifications**: Many manufacturers pursue safety certifications for their Four-Ram BOPs, providing additional assurance to operators regarding the reliability and safety of their equipment.

8. Future Trends in Blowout Prevention Technology

The future of blowout prevention technology looks promising, with several trends expected to shape the development of Four-Ram Blowout Preventers.

1. **Increased Automation**: As the industry moves towards automation, we expect to see more automated systems for operating BOPs. This could enhance response times during emergencies and reduce human error.

2. **Data Analytics**: The integration of data analytics into the monitoring systems of Four-Ram BOPs will provide operators with deeper insights into performance and potential risks, allowing for proactive management of drilling operations.

3. **Sustainability Focus**: With growing environmental concerns, the oil and gas industry is shifting towards more sustainable practices. Future BOP designs may focus on minimizing environmental impact while maintaining safety and efficiency.

9. FAQs

**Q1: What is a Blowout Preventer (BOP)?**

A Blowout Preventer (BOP) is a safety device used in oil and gas drilling to prevent blowouts, which are uncontrolled releases of oil and gas.

**Q2: How does a Four-Ram Blowout Preventer differ from a Two-Ram BOP?**

The Four-Ram BOP has four independent rams, providing enhanced safety and sealing capabilities compared to two-ram models.

**Q3: What industries use Four-Ram Blowout Preventers?**

Four-Ram BOPs are primarily used in the oil and gas industry, both offshore and onshore, to ensure safe drilling operations.

**Q4: Are Four-Ram Blowout Preventers subject to regulatory standards?**

Yes, Four-Ram BOPs must comply with various industry standards and regulations, including those set by the American Petroleum Institute (API).

**Q5: What advancements are being made in Four-Ram Blowout Preventer technology?**

Recent advancements include smart technology integration, improved materials, and enhanced control systems for better performance and safety.

10. Conclusion

The Four-Ram Blowout Preventer plays a critical role in the safety and efficiency of drilling operations in the oil and gas industry. With its advanced design, enhanced safety features, and ability to handle high-pressure scenarios, the newest Four-Ram BOPs stand out as a vital tool in preventing blowouts and ensuring compliance with stringent industry regulations.

As technology continues to evolve, the future of blowout prevention looks promising, with advancements that will further enhance safety and operational efficiency. Companies that invest in the latest Four-Ram Blowout Preventer technology will not only protect their assets but also contribute to a safer and more sustainable drilling industry.

Related News

Contact Us

Mailbox:

tiehu@tiehupetro.com

Telephone:

86-317-2616808

Address:

Yanling Industrial Zone, Renqiu City, Cangzhou City, Hebei Province, China